2026 Top ASRS Systems Innovations and Trends to Watch?

In the fast-evolving world of logistics, ASRS systems are at the forefront of innovation. These automated storage and retrieval systems enhance efficiency and reduce operational costs. Industry expert Dr. Emily Tran emphasizes, "The future of warehousing lies in smart ASRS systems." Her insights reflect the crucial role of technology in shaping the industry.

As we approach 2026, several trends are emerging. The integration of artificial intelligence and machine learning is revolutionizing how ASRS systems operate. Companies are increasingly focusing on eco-friendly designs and sustainable practices. Yet, with these advances come challenges. Many organizations struggle to adapt legacy systems to new technologies.

Companies must reevaluate their approaches continuously. Understanding the strengths and limitations of ASRS systems is essential. As the landscape shifts, staying informed about innovations will be vital for success. The future remains bright but requires careful consideration and strategic planning.

Overview of Automated Storage and Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) are transforming warehousing and logistics. The global ASRS market is projected to reach $12 billion by 2026, driven by e-commerce growth and the need for efficient inventory management. These systems enhance accuracy and speed, making them essential for modern operations.

Implementing ASRS can reduce labor costs by up to 30%. It minimizes human error during storage and retrieval. Companies see a significant increase in throughput and space utilization. However, the initial setup cost can be high. Many firms struggle with integrating new technology into existing systems.

Tip: Invest time in training staff on new systems to maximize benefits. Understanding these technologies is crucial. As ASRS evolves, keeping up with innovations becomes vital. Companies must stay informed about trends to remain competitive. Focus on flexibility to adapt your systems as needs change.

2026 Top ASRS Systems Innovations and Trends to Watch

| Innovation/Trend | Description | Expected Impact | Implementation Timeline |

|---|---|---|---|

| AI Integration | Utilizing artificial intelligence for predictive analytics and decision-making. | Increased efficiency and reduced operational costs. | 2024 - 2026 |

| Robotic Automation | Enhanced use of robotics for sorting and storage tasks. | Improved throughput and accuracy in order fulfillment. | 2025 |

| IoT Connectivity | Integration of IoT devices for real-time monitoring and maintenance. | Enhanced visibility and reduced downtime. | 2024 - 2025 |

| Mobile ASRS Solutions | Use of mobile systems for flexible storage and retrieval operations. | Greater adaptability to changing warehouse needs. | 2026 |

| Sustainability Practices | Focus on energy-efficient systems and eco-friendly materials. | Reduction of carbon footprint and operational costs. | 2024 - 2026 |

Key Innovations in ASRS Technology for 2026

As we approach 2026, the landscape of Automated Storage and Retrieval Systems (ASRS) is evolving rapidly. Key innovations are reshaping how warehouses operate. According to a recent industry report, the global ASRS market is projected to reach $10 billion by 2026, driven by efficiency and automation. Flexibility is emerging as a critical trend. Systems now adapt to varying product sizes and volumes, which enhances overall productivity.

Artificial intelligence is also a game changer. AI algorithms optimize inventory management, predicting stock levels with remarkable accuracy. Reports indicate that AI-driven ASRS can boost retrieval speeds by up to 40%. However, reliance on technology raises concerns. Potential errors in AI predictions can disrupt operations. Proper training and human oversight remain essential to mitigate these risks.

Sustainability is another focal point. Innovative ASRS designs now emphasize energy efficiency. For instance, systems are integrating solar panels and energy recovery systems. Despite these advancements, challenges persist. Not every facility can invest in such technologies. Businesses must weigh the costs and benefits carefully. Balancing innovation with practical constraints will define success in this evolving field.

2026 Top ASRS Systems Innovations and Trends

Emerging Trends Impacting ASRS Adoption in Various Industries

The landscape of Automated Storage and Retrieval Systems (ASRS) is rapidly evolving. Emerging technologies are reshaping how businesses approach warehouse logistics. For many industries, integrating ASRS is not merely a trend; it’s becoming a necessity. Automation enhances efficiency and accuracy in inventory management. However, navigating the complexities of ASRS adoption can be challenging.

One significant trend is the increasing reliance on artificial intelligence. AI can optimize inventory sorting, predicting demand patterns more accurately. Yet, the implementation of such technology is often met with resistance. Staff may fear job displacement. It requires a culture shift. Training and adaptation processes can feel sluggish. There is a need for balance between automation and human oversight.

Sustainability is also driving ASRS innovations. Companies are prioritizing energy-efficient systems. They look to reduce their carbon footprints. However, the initial costs can be a barrier. Many businesses question the return on investment. Without careful analysis, these technologies could remain underutilized. Balancing innovation with practical viability remains a crucial consideration for industries contemplating ASRS integration.

Challenges and Opportunities for ASRS Implementation in 2026

Automated Storage and Retrieval Systems (ASRS) are transforming the logistics landscape. However, their implementation in 2026 presents significant challenges. One key challenge is the integration with existing infrastructure. Older warehouses may struggle to incorporate new systems seamlessly. This can lead to disruptions and increased costs. There is also a steep learning curve for staff who must adapt to high-tech solutions.

On the opportunity side, the growing demand for efficiency is a driving force. Companies are keen to reduce labor costs and increase speed. ASRS can streamline operations significantly. Yet, the initial investment can be daunting. Companies must weigh potential savings against upfront costs. It’s also crucial to consider maintenance and updates after installation.

Moreover, cybersecurity risks are a significant concern. With increased connectivity comes vulnerability. Companies need robust security protocols to protect sensitive data. Although these challenges seem daunting, they also highlight areas for growth. Businesses can learn from early adopters to create better strategies for ASRS. Tackling these obstacles thoughtfully can lead to successful implementations.

Future Directions: Potential Developments in ASRS Systems Beyond 2026

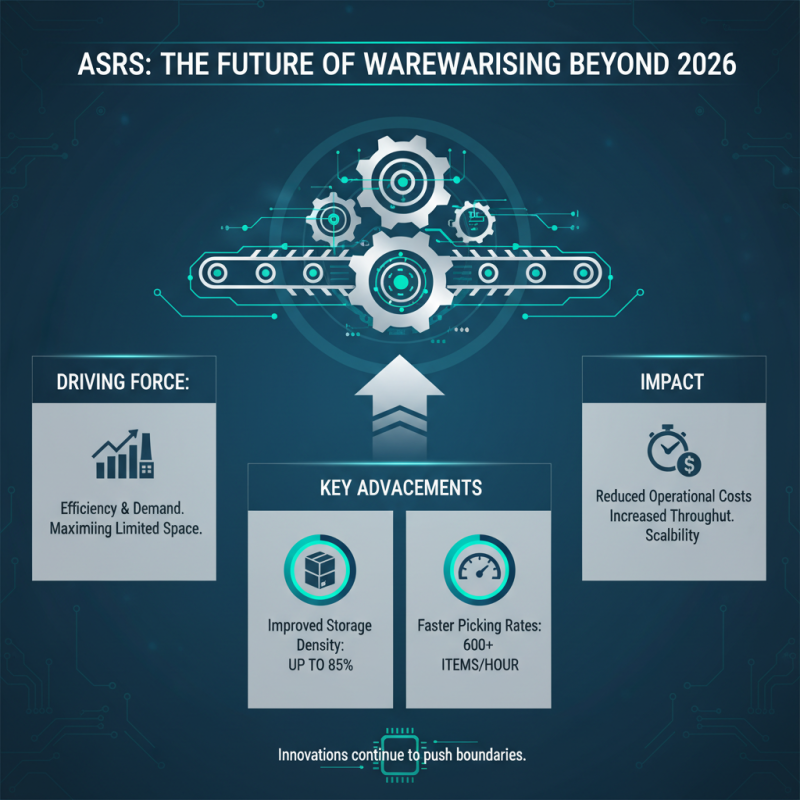

As we look beyond 2026, automated storage and retrieval systems (ASRS) are poised for significant advancements. The increasing demand for efficiency in warehouse operations is a driving force. Reports indicate that ASRS can improve storage density by up to 85%. This is crucial for companies maximizing limited space. Faster picking rates are also essential. Current ASRS technologies can achieve speeds of around 600 items per hour, but innovations could push this further.

Emerging technologies will play a critical role in ASRS evolution. Artificial intelligence and robotics will enhance system adaptability. Flexibility will become key, allowing systems to handle diverse products. Predictive analytics will offer insights for optimizing inventory management. However, transitioning to these advanced systems poses challenges. Integration with existing infrastructure might not be smooth. Many facilities may struggle with training staff on new technologies.

Sustainability is another vital area of focus. Energy-efficient systems could reduce operational costs. A 2022 report highlighted that automated systems could lower energy consumption by nearly 30%. However, initial implementation costs are high. These factors require careful consideration. Stakeholders must navigate these complexities to fully realize the benefits of future ASRS developments.

Related Posts

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

Understanding ASRS System Warehouse: Transform Your Storage Efficiency Today!

-

Why Is Automated Storage Essential for Modern Businesses?

-

Top 10 Benefits of Using Cartesian Robots in Modern Automation Systems