Top 5 Benefits of ASRS Warehouse Systems for Modern Logistics?

In today’s fast-paced logistics industry, ASRS warehouse systems are gaining traction. Experts like Dr. Emily Hart, a prominent figure in logistics technology, point out, “ASRS warehouse systems streamline processes and improve efficiency.” This sentiment reflects the growing shift towards automation in storage and retrieval.

ASRS warehouses utilize advanced technology to manage inventory. These systems offer significant benefits such as space optimization, improved accuracy, and reduced labor costs. For instance, a well-designed ASRS can maximize vertical space, effectively doubling storage capacity. However, the implementation can be complex and costly, often requiring substantial investment in technology and training.

Adopting ASRS warehouse solutions is not without challenges. Organizations must weigh these benefits against potential disruptions during installation. Despite these hurdles, many companies find that the long-term gains outweigh the initial setbacks. With the logistics landscape constantly evolving, understanding the advantages of ASRS can be critical for staying competitive.

Overview of ASRS Warehouse Systems in Modern Logistics

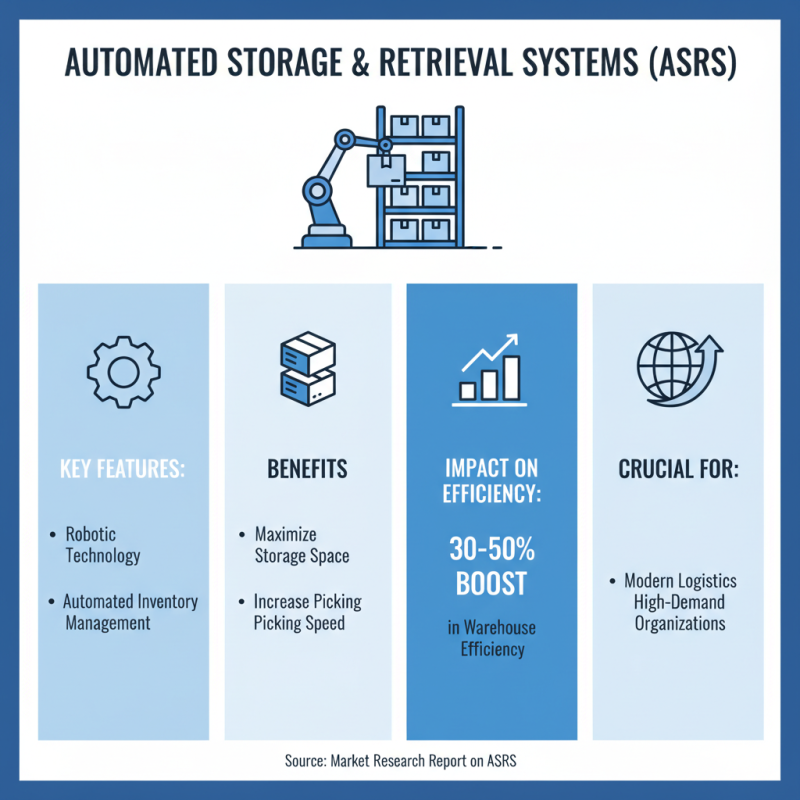

Automated Storage and Retrieval Systems (ASRS) have transformed modern logistics. These systems utilize robotic technology for inventory management. They help in maximizing storage space and increasing picking speed. According to a report by market research, ASRS can boost warehouse efficiency by 30% to 50%. This advancement has been pivotal for organizations facing rising demands.

The integration of ASRS in logistics should not be overlooked. It offers precision in managing inventory. Automation eliminates human error, but it comes with challenges. Maintenance and breakdowns can disrupt operations. On the other hand, 75% of companies report lower labor costs after implementing ASRS. The initial investment may be high, but long-term savings often outweigh costs.

Logistics providers aim for sustainability. ASRS can reduce energy consumption by up to 40% compared to traditional systems. This shift not only benefits businesses but also the environment. However, firms must continuously evaluate their operations. It’s essential to adapt to changing technologies and consumer demands. Embracing innovation is critical, yet companies must remain aware of potential pitfalls.

Increased Efficiency and Space Saving through Automation

Automated Storage and Retrieval Systems (ASRS) have transformed modern logistics. These systems boost efficiency and save space. A report by the Logistics Management Institute shows that ASRS can increase productivity by up to 30%. This is mainly due to reduced retrieval times and minimized labor costs. Automation allows workers to focus on more complex tasks, driving overall performance.

The footprint of warehouses can often consume valuable real estate. ASRS can cut the required space by as much as 40%. This space-saving is vital in urban areas where real estate costs are high. By using vertical storage and compact shelving, companies can store more in less area. This shift means less money spent on rent and more resources available for growth.

However, implementing ASRS isn't without challenges. The initial cost can be substantial, requiring careful financial planning. Companies must ensure their workforce is trained to operate new technologies effectively. Some employees may resist automation, fearing job loss. It’s crucial to address these concerns openly. Balancing efficiency gains with human factors remains an ongoing task in the logistics sector.

Top 5 Benefits of ASRS Warehouse Systems for Modern Logistics

| Benefit | Description | Impact (%) |

|---|---|---|

| Increased Efficiency | Automation of storage and retrieval processes speeds up operations. | 30 |

| Space Optimization | Maximizes storage space through vertical stacking and compact designs. | 25 |

| Cost Reduction | Lower operational costs through reduced labor and higher accuracy. | 20 |

| Enhanced Inventory Control | Improved tracking and management of stock levels with real-time data. | 15 |

| Scalability | Easily scalable to accommodate changing storage needs. | 10 |

Enhanced Inventory Management and Accuracy with ASRS

Automated Storage and Retrieval Systems (ASRS) significantly enhance inventory management in modern warehouses. They streamline operations, reducing the chances of errors. By automating the picking and storing processes, these systems help maintain accurate inventory records. This accuracy benefits order fulfillment and reduces overstocking issues.

Storing items in compact spaces can be challenging. ASRS maximizes storage efficiency by using vertical space. This design not only saves room but also improves access to products. With real-time data tracking, businesses can monitor stock levels closely. An efficient ASRS setup offers insights into inventory turnover, helping to adjust purchasing decisions.

**Tip:** Regularly analyze your inventory data. This practice can highlight slow-moving items. It enables proactive measures for better stock management.

Another consideration is staff training. Employees must understand how to operate ASRS systems efficiently. Poor training might lead to mistakes, resulting in discrepancies. Address these challenges through ongoing training.

**Tip:** Schedule periodic training sessions. Keep staff updated on best practices and new systems. Continuous learning fosters a smoother workflow.

Top 5 Benefits of ASRS Warehouse Systems for Modern Logistics

Reduction of Labor Costs and Safety Risks in Warehousing

Automated Storage and Retrieval Systems (ASRS) play a vital role in modern warehousing. They significantly reduce labor costs. By automating the storage and retrieval processes, companies can operate with fewer staff members. This not only saves money on wages but also minimizes training expenses. Workers are often required to handle heavy items, increasing injury risks. Automation can lower these risks considerably.

Safety becomes a major concern in busy warehouses. Automated systems can handle hazardous materials more effectively. Employees can focus on tasks like quality control and customer service rather than physical labor. However, companies must still invest in training for effective interaction with these systems. Regular maintenance is crucial to avoid breakdowns that can lead to accidents or operational delays.

In integrating ASRS, companies face challenges. The upfront costs can be daunting. Additionally, there might be initial resistance from employees. They may feel threatened by automation, fearing job losses. Providing clear communication about the advantages of ASRS can help ease these worries. Addressing these concerns is essential for a smooth transition to automation, ensuring both efficiency and a safe working environment.

Scalability and Flexibility for Evolving Logistics Needs

The modern logistics landscape demands agility.

ASRS (Automated Storage and Retrieval Systems) offer unparalleled scalability and flexibility. As businesses grow, their inventory management needs shift. Traditional systems often struggle to keep pace. However, ASRS can adapt seamlessly, handling fluctuating demand with ease.

According to a recent study by the Warehousing Education and Research Council, companies using ASRS reported a 30% increase in storage efficiency. This adaptation means facilities can expand without massive investments in infrastructure. Instead, businesses can utilize vertical space and optimize floor layout effectively. This flexibility allows warehouses to respond quickly to market changes.

Yet, challenges exist. The initial setup can be complex. Integrating ASRS requires careful planning. Companies may face resistance from staff unfamiliar with automation. Training is essential to ensure operations run smoothly. Overcoming these hurdles could lead to improved efficiency and lower operational costs in the long run. Adjustments during implementation must be expected for a successful transition.

Related Posts

-

Understanding ASRS System Warehouse: Transform Your Storage Efficiency Today!

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

2026 Top ASRS Systems Innovations and Trends to Watch?

-

Why Is Automated Storage Essential for Modern Businesses?

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

-

Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing