Top 10 Benefits of Using Industrial Robot Arms in Modern Manufacturing

In today's rapidly evolving manufacturing landscape, the integration of **industrial robot arms** has become a pivotal factor for companies striving for efficiency and competitiveness. According to a report from the International Federation of Robotics, the adoption of industrial robots is expected to grow at a remarkable rate of 15% annually, which highlights the increasing reliance on automation within manufacturing sectors worldwide. Expert in automation technology, Dr. Linda Simmons, states, "The future of manufacturing lies in the seamless collaboration between human workers and industrial robot arms, which enhances productivity and reduces operational costs."

The benefits derived from utilizing **industrial robot arms** extend beyond mere productivity improvements; they also encompass enhanced precision, safety, and scalability. A study published by McKinsey & Company indicates that companies employing robotic automation can achieve up to a 30% increase in production output while significantly lowering error rates. As manufacturers navigate the complexities of contemporary production demands, the strategic implementation of industrial robot arms can streamline workflows and adapt to fluctuating market needs, ultimately positioning organizations for sustainable growth and innovation.

In summary, the compelling advantages of **industrial robot arms** are reshaping the furniture of modern manufacturing. Industries that harness these technologies not only boost their operational capabilities but also pave the way for future advancements in automation. As we delve into the top benefits of adopting these sophisticated tools, it becomes clear that embracing industrial robot arms is no longer optional, but essential for thriving in the competitive marketplace.

Benefits of Increased Precision and Accuracy in Manufacturing Processes

The use of industrial robot arms in modern manufacturing is transforming production lines by enhancing precision and accuracy significantly. According to a report from the International Federation of Robotics (IFR), industries that have adopted robotic automation have seen an impressive 35% increase in production accuracy. This elevated level of precision minimizes errors, reduces waste, and ultimately leads to higher quality end products. Furthermore, these robots can perform repetitive tasks with a reliability that often surpasses human capability, thereby ensuring consistency in manufacturing processes.

Investing in robotic systems not only boosts precision but also optimizes resource allocation. A study by McKinsey & Company highlights that companies utilizing automation report a 20-30% reduction in manufacturing costs through efficient process management. As industries strive for lean manufacturing, the role of robotic arms becomes even more critical in achieving stringent quality standards.

Tips: When considering the integration of robotic arms, focus on the specific tasks that would benefit most from increased accuracy. Additionally, regularly calibrate and maintain robotic systems to ensure they operate at optimum precision levels. Investing in staff training is also vital, as skilled operators can maximize the benefits of automation, leading to a smoother transition and better overall performance.

Enhanced Safety and Reduced Workplace Hazards with Robot Arms

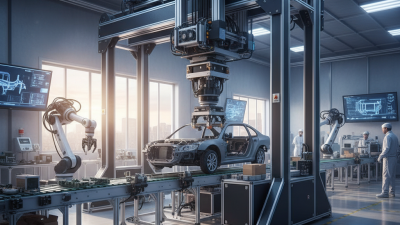

The introduction of industrial robot arms in manufacturing has significantly transformed workplace safety protocols. These advanced machines are designed to take on repetitive and hazardous tasks, minimizing the exposure of human workers to dangerous environments. By deploying robot arms for tasks such as welding, painting, or heavy lifting, companies can significantly reduce the risk of injuries that often arise from manual labor. As these robotic systems are engineered to maintain precision and consistency, they also lower the chances of accidents caused by human error, ensuring a safer working environment.

Moreover, the integration of robot arms in manufacturing processes supports enhanced safety measures through real-time monitoring and automated responses. Many modern robotic systems come equipped with sensors and AI technologies that can detect potential hazards, immediately stopping operations if a risk is identified. This proactive approach not only protects workers but also fosters a culture of safety within the organization. By shifting dangerous responsibilities away from human operators, businesses can prioritize their employees' well-being while simultaneously boosting productivity and efficiency.

Boosting Production Efficiency and Throughput in Industrial Settings

In today's competitive landscape, the integration of industrial robot arms has become a cornerstone for enhancing production efficiency in manufacturing. These advanced systems significantly streamline operations by automating repetitive and labor-intensive tasks, allowing human workers to focus on more complex and value-added activities. The result is a marked increase in throughput, as robotic arms can execute tasks at a speed and precision unattainable by human hands alone. This capability not only accelerates production lines but also reduces the likelihood of errors, leading to higher quality products and less waste.

Moreover, the versatility of industrial robot arms allows them to be reprogrammed and adapted for various tasks, making them an invaluable asset in diverse manufacturing environments. Their ability to quickly switch between applications, whether assembling parts or handling materials, ensures that production stays agile and responsive to market demands. This flexibility not only boosts overall operational efficiency but also reduces downtime, further enhancing throughput. As a result, manufacturers that embrace the use of robotic arms are better positioned to meet the challenges of modern production while maintaining a competitive edge in the marketplace.

Top 10 Benefits of Using Industrial Robot Arms in Modern Manufacturing - Boosting Production Efficiency and Throughput in Industrial Settings

| Benefit | Description | Impact on Efficiency | Example Metrics |

|---|---|---|---|

| Increased Production Speed | Robot arms can perform tasks faster than human workers. | Reduces cycle time by up to 30%. | Production rate increase from 100 to 130 units/hour. |

| Enhanced Precision | Consistent quality through precise movements. | Defect rates drop significantly. | Defects reduced from 5% to 1%. |

| Reduced Labor Costs | Less reliance on manual labor leads to cost savings. | Labor costs can be reduced by 25%. | Monthly savings of $10,000. |

| Improved Worker Safety | Reduces human exposure to hazardous tasks. | Lower incident rates of workplace injuries. | Injuries decreased from 20 to 5 per year. |

| Increased Flexibility | Easily reprogrammable for different tasks. | Quick changeover times enhance adaptability. | Changeover time reduced from hours to minutes. |

| Longer Operational Hours | Can operate continuously without breaks. | Increases total operational uptime. | Uptime improved from 70% to 90%. |

| Consistent Production Quality | Reduces variability in production processes. | Maintains a high standard of quality. | Quality metrics improved from 80% to 98% compliance. |

| Scalability | Easily scaled up or down based on demand. | Facilitates production adjustments. | Ability to increase output by 50% during peak times. |

| Integration with Industry 4.0 | Compatible with smart factory technologies. | Enhances data collection and analytics. | Utilization of real-time data to optimize processes. |

| Cost Effectiveness | Initial investment returned through savings. | ROI achieved within 2-3 years. | Estimated savings of $50,000 annually. |

Cost Reduction through Automation and Labor Savings in Manufacturing

The integration of industrial robot arms in modern manufacturing has transformed the operational landscape, especially in terms of cost reduction. By automating repetitive tasks, businesses can significantly lower labor costs while maximizing production efficiency. Automation allows companies to employ a smaller workforce for highly skilled tasks, leading to a reduction in wage expenses and benefits. Moreover, robots operate continuously without the need for breaks, which means that production lines can run for extended periods, further driving down operational costs.

Tips: When considering automation, evaluate the specific tasks that are repetitive and time-consuming, as these are prime candidates for robot intervention. Additionally, investing in training for your existing workforce to manage and maintain these robotic systems can lead to smoother transitions and optimized productivity.

Another key benefit of using industrial robot arms is the consistency and precision they bring to the manufacturing process. This not only reduces waste from human error but also ensures higher quality output, which can lead to cost savings in materials and rework. Over time, the initial investment in robotic technology can pay off considerably through the accumulation of these savings.

Tips: Regularly assess the performance metrics of your robotic systems to identify any areas for improvement, as this can lead to enhanced efficiency and further cost reductions. Additionally, seeking feedback from operators can provide insights into potential refinements in the workflow.

Cost Reduction through Automation with Industrial Robot Arms

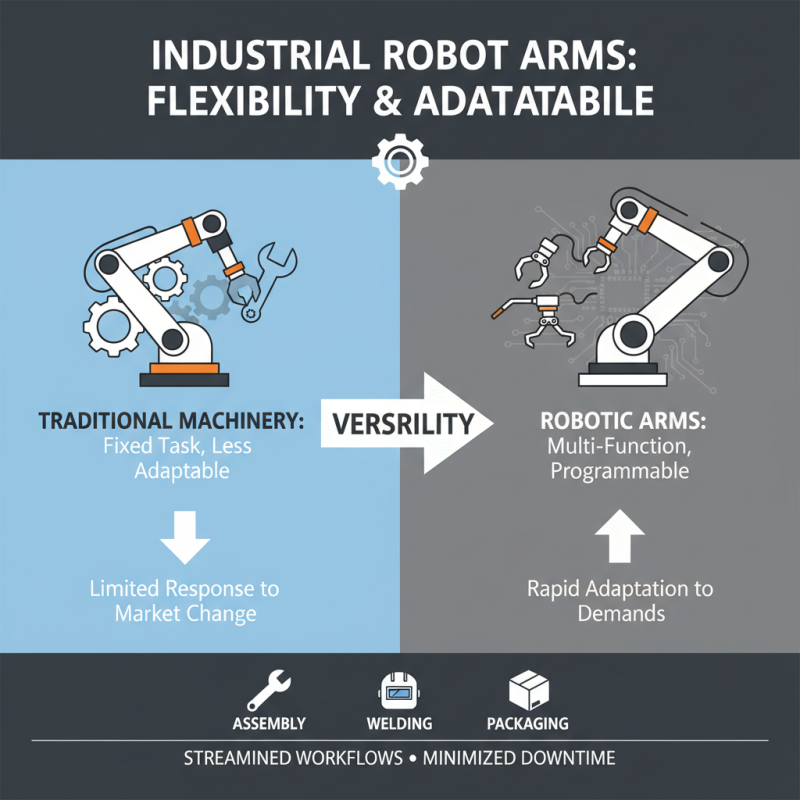

Flexibility and Adaptability of Robot Arms for Various Manufacturing Tasks

The flexibility and adaptability of industrial robot arms make them an invaluable asset in modern manufacturing environments. Unlike traditional machinery, which is typically optimized for a specific task, robotic arms can be programmed or reconfigured to handle a wide variety of functions. This versatility allows manufacturers to respond rapidly to changing market demands and production requirements. For instance, a single robot arm may switch from assembling components to welding or packaging, streamlining workflows and minimizing downtime.

Moreover, the ease of programming and integration of robotic systems contributes to their adaptability. With advancements in artificial intelligence and machine learning, industrial robot arms can learn from their surroundings and optimize their performance in real-time. This capability enhances not only the efficiency of individual tasks but also the overall productivity of the manufacturing process. As a result, businesses can achieve higher output rates and maintain quality standards while also saving on labor costs. The ability to quickly adjust to new designs or production methods further underscores the critical role of robot arms in the contemporary manufacturing landscape.

Related Posts

-

Top 10 Fanuc Robot Applications in Manufacturing and Automation Industry

-

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today

-

Top 10 Benefits of Automated Storage for Efficient Inventory Management

-

Why Is Automated Storage Essential for Modern Businesses?

-

How to Choose the Right Gantry Robot for Your Automation Needs

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase