2026 Best ASRS Racking System Solutions for Efficient Warehousing?

In the rapidly evolving landscape of logistics, the ASRS racking system has emerged as a game changer. These systems automate storage and retrieval processes, optimizing warehouse space. With the rise of e-commerce, efficient warehousing solutions have never been more crucial. Companies face increasing demands for speed and accuracy.

However, not all ASRS racking systems are created equal. Choosing the right solution requires careful consideration. Factors like warehouse layout, inventory type, and operational needs play significant roles. Some systems may be too complex for smaller operations, while others can be overly simplistic for larger ones.

The challenge lies in balancing efficiency with practicality. Implementing an ASRS racking system can significantly boost productivity, but it requires thoughtful integration. Companies must also account for potential pitfalls, like technology compatibility and employee training needs. This reflection on what works and what doesn't creates opportunities for better solutions. Hence, exploring the best ASRS racking system solutions for 2026 is vital for future success.

The Importance of ASRS Racking Systems in Modern Warehousing

Automated Storage and Retrieval Systems (ASRS) are transforming modern warehouses. They use technology to enhance storage efficiency. ASRS optimizes space, maximizing vertical storage. This is crucial in limited spaces.

Implementing ASRS can reduce labor costs. Human workers can focus on tasks that require decision-making. Yet, reliance on technology may pose challenges. System failures can disrupt operations. Moreover, maintenance requires skilled personnel. Investing in training is essential.

Choosing the right racking system is vital. It needs to fit the specific needs of the warehouse. Flexibility is important; demands can change rapidly. ASRS can adapt, but that’s not always seamless.

Regular assessments of systems and processes are necessary. This reflection can ensure continuous improvement in warehousing operations.

Top ASRS Technologies to Enhance Space Utilization in Warehouses

In modern warehousing, effective space utilization is critical. Automated Storage and Retrieval Systems (ASRS) have emerged as key solutions. These systems can increase storage density by up to 60%, allowing businesses to maximize their square footage. Data suggests that warehouses using ASRS can improve picking efficiency by 25% or more. This leads to significant labor savings and higher throughput.

Implementing ASRS also presents challenges. While the initial investment can be substantial, the long-term benefits often justify it. However, companies must carefully assess their needs. A one-size-fits-all approach does not work. Some operations may require specific configurations to optimize the racking system. Striking the right balance is essential for success.

In addition, maintenance of ASRS is critical. Neglecting routine checks can lead to system failures. Regular training for warehouse staff on these systems is necessary to prevent operational hiccups. Proper understanding of ASRS technology can take time. Continuous improvement and adaptation to evolving technologies should remain a top priority. The future of warehousing depends significantly on how effectively these challenges are addressed.

2026 Best ASRS Racking System Solutions for Efficient Warehousing

Comparative Analysis of ASRS Racking Solutions Based on Industry Case Studies

The demand for efficient warehousing is growing, prompting many industries to explore

Automated Storage and Retrieval Systems (ASRS). These systems enhance

space utilization and improve

order fulfillment speed. However, it is crucial to analyze different ASRS racking solutions.

Understanding real-world applications can reveal strengths and weaknesses that affect

overall effectiveness.

Industry case studies highlight the diverse challenges faced during implementation. Some companies

experience bottlenecks due to poor system design. Others struggle with maintaining their

equipment. Reviewing these cases can help businesses avoid similar pitfalls. Learning from past

experiences fosters better decisions.

Tip: Always consider your specific needs before choosing an ASRS solution.

Customization may lead to increased efficiency.

Another aspect to evaluate is the scalability of the racking system. As businesses grow, their

warehousing needs will evolve. An adaptable ASRS solution can accommodate this growth

without requiring a complete overhaul. However, some installations lack this flexibility, which

can hinder operations later.

Tip: Conduct regular assessments of your racking system. This helps identify

areas needing improvement or adjustment.

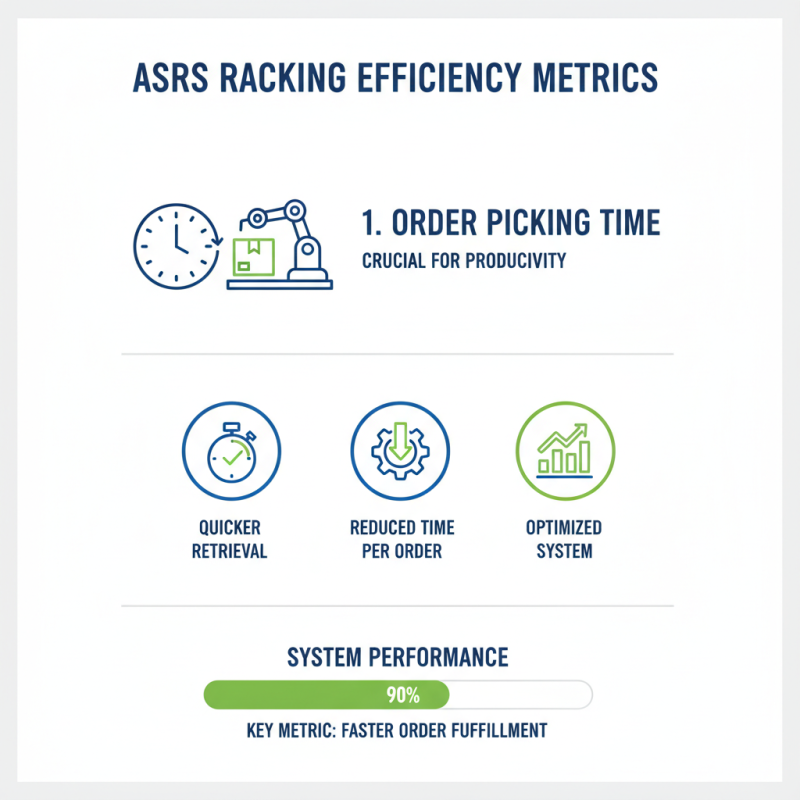

Key Performance Metrics for Evaluating ASRS Racking System Efficiency

When evaluating the efficiency of ASRS racking systems, key performance metrics are essential. These metrics help to determine how well a system operates without getting bogged down by unnecessary complexity. One important metric is the order picking time. The quicker the system retrieves items, the better it performs. A well-optimized system reduces the time spent on each order, crucial for overall productivity.

Another measure is storage density, which refers to how much product can be stored in a given space. Higher storage density leads to more efficient use of warehousing space. However, it might result in difficulties accessing certain items. Striking a balance between space and accessibility is vital. Additionally, consider the system's throughput. This metric indicates how many items can be handled within a specific timeframe. It's a key indicator of operational efficiency but can fluctuate depending on system design and user interaction.

Reflecting on maintenance and operational issues is also important. Regular downtime for repairs can hinder an ASRS’s efficiency. Understanding the root causes of failures can lead to better decision-making in the future. Ultimately, the focus should not just be on the technology itself but also on the human element involved in its operation. Efficient training and clear communication are critical for harnessing the full potential of an ASRS racking system.

Future Trends in ASRS Racking Solutions and Their Impact on Supply Chains

The future of Automated Storage and Retrieval Systems (ASRS) racking solutions is evolving rapidly. These advancements aim to enhance efficiency in warehousing operations. As supply chains face increased demands, businesses are adopting smarter racking systems. These systems not only maximize storage density but also reduce handling times. By automating processes, companies can respond quicker to consumer needs.

Tips: Evaluate your current storage setup. Identify areas where automation can ease workload. Consider how space utilization affects your overall operation.

Emerging trends include modular designs and AI integration in racking systems. Modular systems allow for flexibility in warehouse layouts. AI can optimize inventory management and reduce errors. However, implementing these technologies can cause growing pains. Staff may need time to adapt. Poor training can lead to inefficiencies and frustration.

Tips: Invest in comprehensive training for employees. Ensure everyone understands the new systems. Regular feedback sessions can help address concerns.

Related Posts

-

Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

2025 How to Choose the Best Machine Tending Robot for Your Business Needs

-

10 Best Automated Storage Solutions for Efficient Space Management

-

Top 10 Benefits of Using XYZ Gantry in Your Projects?

-

How to Efficiently Use XYZ Gantry for Your Next Project Guide