2026 Best Automated Material Handling Solutions for Efficient Warehousing?

In today's fast-paced world, businesses are seeking efficiency in every operation. Automated material handling is at the forefront of this transformation. In 2026, companies will prioritize innovative solutions. These solutions streamline processes and reduce human error.

Imagine warehouses operating at peak efficiency. Goods move swiftly from one point to another, thanks to automation. Conveyor belts and robotic systems play vital roles. They eliminate manual labor and speed up deliveries. However, the transition to automated systems is not without challenges. Many firms struggle with integration and costs.

As we explore the best automated material handling solutions for 2026, we must consider real-world implications. Companies need to assess their specific needs. Investing in the wrong technology can lead to setbacks. The goal is not just automation for the sake of it, but for true efficiency.

Overview of Automated Material Handling Solutions in Warehousing

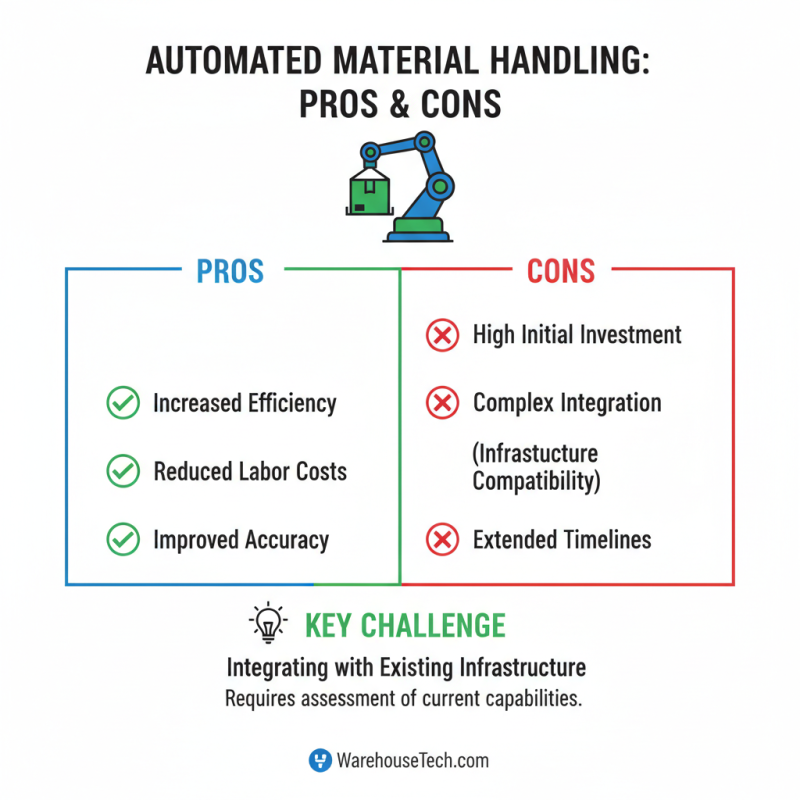

Automated material handling solutions revolutionize warehousing. They streamline processes, reduce labor costs, and enhance accuracy. These systems utilize robotics and software to move products efficiently. Automated Guided Vehicles (AGVs) are a prime example. They navigate without human intervention, transporting goods across vast spaces. Their ability to operate continuously boosts productivity significantly.

However, the implementation of these technologies can be challenging. Integrating new systems into existing operations may cause disruptions. For some businesses, the initial investment is daunting. Yet, the potential for long-term savings is undeniable. In many cases, organizations face a learning curve. Employees need training to interact effectively with automated systems. This adjustment period can lead to temporary inefficiencies.

Moreover, not all tasks can be automated seamlessly. Some complex operations still require a human touch. Considerations around safety also play a crucial role. Balancing automation with human oversight is essential. Reflecting on these challenges is necessary to maximize benefits. Adopting new technologies should be approached with caution. Every organization must assess its unique needs before diving into automation.

2026 Best Automated Material Handling Solutions for Efficient Warehousing

Key Technologies Driving Efficiency in Automated Warehousing

Automated material handling solutions have transformed warehousing. Key technologies are driving this efficiency. Robotics, for instance, play a pivotal role in warehouse operations. They can move various items quickly. This reduces manual labor and increases accuracy. The use of drones is also growing. Drones can scan inventory in high locations. They save time and minimize human error.

Another technology to consider is the use of automated guided vehicles (AGVs). These vehicles transport goods between different areas of a warehouse. They operate autonomously, which streamlines operations. However, reliance on AGVs can lead to challenges. If the system fails, delays can occur. This dependency on technology calls for continuous evaluation.

Artificial intelligence (AI) further enhances material handling. AI analyzes data to predict inventory needs. Implementing AI can optimize stock levels and reduce waste. Yet, it requires careful data management. Poor data quality can lead to misguided decisions. Adopting new technologies demands balancing innovation and potential pitfalls.

Benefits of Implementing Automated Systems in Warehouse Operations

The benefits of implementing automated systems in warehouse operations are significant. Reports suggest that automated material handling can reduce operating costs by up to 25%. These systems streamline processes, improving accuracy and speed. For instance, automated guided vehicles (AGVs) can move goods with minimal human intervention, resulting in fewer errors.

Tips: Consider your warehouse layout. Proper design can enhance system efficiency. Measure current workflow patterns. Identify bottlenecks that automation can resolve.

Employee satisfaction often improves too. Automation minimizes repetitive tasks. This allows workers to focus on more complex responsibilities. However, the transition isn't always seamless. Workers may resist change, fearing job losses. Communication is key. Companies need to highlight how technology can create new roles.

Tips: Involve employees during the planning stages. Their insights can shape a smoother transition. Train staff regularly to reduce anxiety around new systems.

Challenges and Considerations in Automated Material Handling

Automated material handling systems promise efficiency in warehousing. However, they come with challenges. One challenge is the integration process. Existing infrastructure may not be compatible with new systems. This can lead to increased costs and extended timelines. It's essential to assess current capabilities before implementing automation.

Training employees is another significant consideration. Workers must adapt to new technologies. Without proper training, productivity may decline. Companies often underestimate the time and resources needed for effective training. Additionally, there is the issue of maintenance. Automated systems require ongoing care to function optimally. Neglecting this can lead to system failures and operational delays.

Despite the benefits of automation, these challenges cannot be overlooked. Planning and adaptability are crucial. Organizations must prioritize thorough evaluation and employee engagement. Only then can they realize the true potential of automated material handling solutions while navigating complex obstacles. Balancing innovation with practicality is key to success.

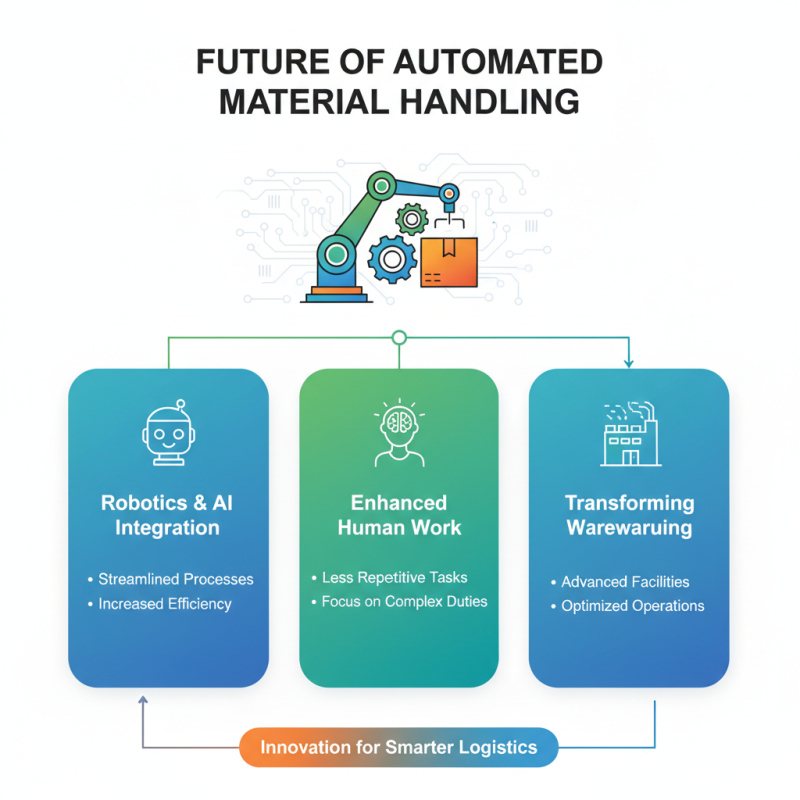

Future Trends in Automated Handling Solutions for Warehousing

The future of automated material handling solutions is exciting. Advancements are transforming warehousing. More facilities are adopting robotics and AI technologies to streamline processes. Automation is not just about replacing humans but enhancing their work. Less labor-intensive tasks are being illuminated, allowing human workers to focus on more complex duties.

One trend is the increased use of mobile robots. These machines can navigate aisles seamlessly, transporting goods without human intervention. They often communicate with each other to optimize routes. However, this technology is not flawless. Malfunctions can occur, causing delays. Employees still need training to handle these new systems effectively.

Another promising development is the integration of data analytics. Real-time data help managers make informed decisions. Stock levels and order statuses can be monitored closely. Yet, relying too much on data may have its pitfalls. Inaccurate data inputs can lead to poor decision-making. A balanced approach is essential to navigate these challenges. Embracing these trends can lead to a more efficient warehouse setup, but without caution, opportunities may be missed.

Related Posts

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

Why Is Automated Storage Essential for Modern Businesses?

-

What is Automated Storage and How Does it Benefit Your Business

-

Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions

-

Understanding ASRS System Warehouse: Transform Your Storage Efficiency Today!

-

Top 10 Benefits of Using Industrial Robot Arms in Modern Manufacturing