10 Best Automated Storage Solutions for Efficient Space Management

In today's fast-paced world, the efficient management of space has become a critical focal point for various industries, including warehouses, offices, and retail environments. As the demand for streamlined operations grows, companies are increasingly turning to automated storage solutions to maximize their available space while simultaneously enhancing productivity. Automated storage systems not only optimize the use of vertical and horizontal space but also reduce labor costs, minimize human error, and expedite the retrieval process, making them a smart investment for businesses looking to improve their efficiency.

This article will explore the ten best automated storage solutions, each designed to address the diverse needs of modern enterprises. From compact designs that fit into tight spaces to expansive systems capable of handling large inventories, these solutions demonstrate the versatility and innovation in storage technology. By leveraging automated storage, businesses can maintain a competitive edge in their respective markets, ensuring that they meet customer demands swiftly and accurately. As we delve into these top solutions, you'll discover how selecting the right automated storage system can transform your space management practices, ultimately leading to improved operational effectiveness and cost savings.

The Growing Demand for Automated Storage Solutions in Modern Warehousing

The demand for automated storage solutions in modern warehousing is on the rise, largely driven by the need for efficiency and optimization in operations. According to a recent report by Mordor Intelligence, the global automated storage and retrieval systems market is expected to grow at a CAGR of 12.3% from 2021 to 2026, highlighting the increasing adoption of technology in supply chain management. This growth is primarily attributed to the burgeoning e-commerce industry, which requires fast and accurate fulfillment processes. Automated systems not only improve inventory management but also reduce operational costs by minimizing labor requirements and maximizing space utilization.

Moreover, the growing focus on inventory accuracy and real-time data analytics is pushing warehouses to adopt automated storage solutions. A study conducted by Logistics Management indicates that businesses utilizing automated systems saw a 30% improvement in inventory accuracy, significantly reducing the risks associated with stockouts and overstock situations. The implementation of automated guided vehicles (AGVs) and robotic picking systems is revolutionizing how goods are stored, retrieved, and handled within warehouses, allowing for higher throughput and better response times. This trend aligns with broader shifts towards Industry 4.0, where interconnected innovations enhance productivity and operational agility in the logistics sector.

10 Best Automated Storage Solutions for Efficient Space Management

| Solution Type | Storage Capacity (cubic meters) | Automation Level | Energy Efficiency Rating | Average Cost (USD) |

|---|---|---|---|---|

| Robotic Shuttle System | 2000 | High | A++ | $300,000 |

| Automated Guided Vehicles (AGVs) | 1500 | Medium | A+ | $200,000 |

| Vertical Lift Module | 500 | High | A | $150,000 |

| Automated Storage & Retrieval System (AS/RS) | 3000 | High | A++ | $400,000 |

| Mini Load AS/RS | 800 | Medium | A+ | $180,000 |

Key Features of Effective Automated Storage Systems by Industry Standards

Automated storage solutions have revolutionized space management across various industries, optimizing efficiency while minimizing the footprint of operations. According to the Warehousing and Fulfillment 2023 Industry Report, businesses implementing automated storage systems have reported up to a 30% increase in space utilization. These systems leverage advanced technology, such as robotics and software integrations, to automate inventory handling, allowing for more precise and efficient storage of goods.

Key features that define effective automated storage systems include modular design, real-time tracking, and adaptability to varying inventory types. A study by the Automated Storage and Retrieval Systems (AS/RS) Association highlighted that systems featuring real-time inventory tracking enable companies to achieve a 25% reduction in order fulfillment times. This efficiency not only enhances customer satisfaction but also lowers operational costs by minimizing excess stock and optimizing order processing. Moreover, the ability to adapt to diverse operational needs ensures that businesses from retail to manufacturing can maximize their storage capacity and streamline workflows effectively.

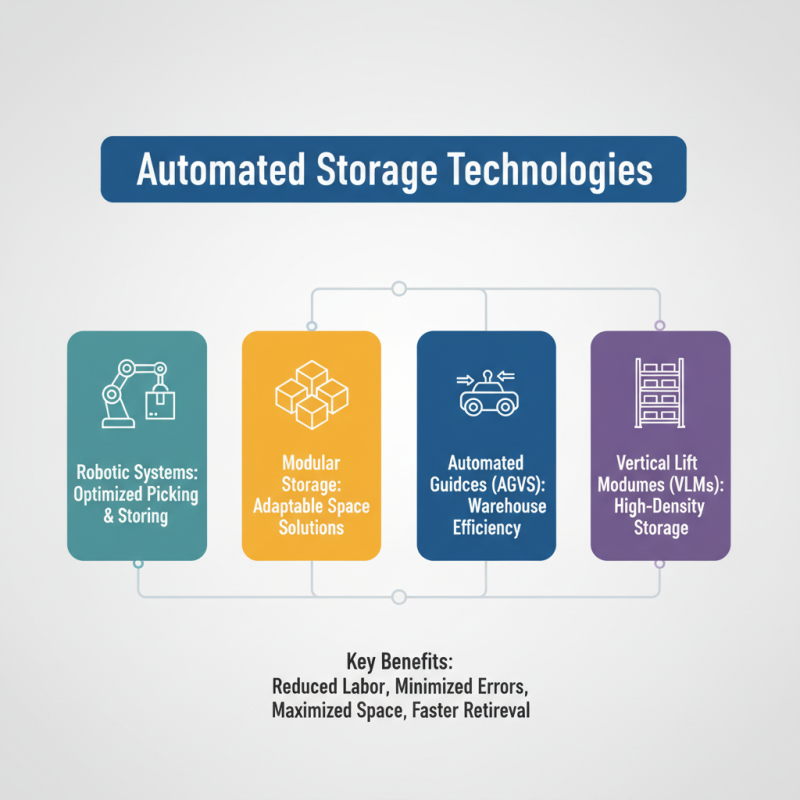

Comparative Analysis of Automated Storage Technologies and Their Applications

The landscape of automated storage technologies has evolved significantly, offering diverse solutions tailored to various applications across industries. From robotic systems that optimize picking and storing to modular storage units that adapt to different spaces, each solution presents unique advantages. For instance, automated guided vehicles (AGVs) can navigate through existing environments, enhancing efficiency in warehouses by reducing manual labor and minimizing errors. Additionally, vertical lift modules (VLMs) provide high-density storage options, significantly maximizing vertical space while ensuring quick retrieval of items, making them ideal for environments with limited floor space.

When comparing these automated systems, it is essential to consider factors such as scalability, integration capabilities, and cost-effectiveness. Some systems, like shuttle-based solutions, offer flexibility and can quickly adapt to changing inventory needs, making them suitable for fast-paced operations. On the other hand, integrated software systems that manage inventory and logistics play a crucial role in optimizing overall performance, ensuring that automated storage solutions not only enhance space management but also align with broader organizational goals. Ultimately, the right choice depends on individual operational requirements and the specific challenges that a business aims to address in its quest for efficiency.

Cost-Benefit Analysis: ROI of Implementing Automated Storage Solutions

The implementation of automated storage solutions presents a compelling case for businesses seeking to optimize their operational efficiency. A thorough cost-benefit analysis reveals that while the initial investment may appear significant, the long-term return on investment (ROI) justifies the expenditure. Automated systems allow for substantial reductions in labor costs, as they minimize the need for manual handling and streamline inventory management processes. This reduction in labor not only lowers costs but also reallocates workforce resources to more strategic tasks that can drive business growth.

Moreover, automated storage solutions typically enhance space utilization, turning previously wasted areas into productive storage locations. The increased capacity leads to greater inventory management efficiency, reducing the likelihood of stockouts or overstock situations that can adversely impact cash flow. Furthermore, the precision of automated systems decreases the risk of human error, which can result in costly mistakes. By quantifying factors such as saved labor hours, increased sales from improved stock availability, and reduced error rates, businesses can clearly see the financial benefits of embracing automation. Ultimately, this paradigm shift not only fosters a more organized environment but also lays the foundation for sustainable growth in an increasingly competitive market.

Cost-Benefit Analysis of Automated Storage Solutions

This chart illustrates the estimated return on investment (ROI) for various automated storage solutions across different metrics such as cost savings, space efficiency, and time saved in operations.

Case Studies: Successful Integration of Automated Storage in Various Sectors

Automated storage solutions have emerged as a transformative approach across various sectors, demonstrating their efficacy in optimizing space management and streamlining operations. For instance, in the retail sector, a leading supermarket chain reported a 30% increase in inventory turnover after integrating automated storage systems. This shift allowed them to utilize vertical space more effectively, reducing floor space requirements by approximately 25%. Furthermore, warehouses employing automated solutions have seen a 40% improvement in picking accuracy, significantly enhancing overall efficiency.

In healthcare, automated storage has revolutionized inventory management in hospitals, resulting in a notable decline in the time staff spend retrieving medical supplies. A case study from a major hospital system indicated a 50% reduction in the time taken to access critical supplies, resulting in improved patient care. By adopting these systems, they not only saved physical space but also reduced the risk of stockouts and related disruptions.

Tips: When considering the integration of automated storage solutions in your organization, start by conducting a comprehensive analysis of your current storage practices. Identifying underutilized space and inefficient workflows can provide a clearer picture of how automated systems can enhance productivity. Additionally, engaging with experts in the field to understand the latest technological advancements can ensure you choose a solution that aligns well with your operational needs.

Related Posts

-

What is Automated Storage and How Does it Benefit Your Business

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

Why Is Automated Storage Essential for Modern Businesses?

-

How to Choose the Right Pick and Place Robot for Your Automation Needs

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity