2026 Best XYZ Gantry Systems for Precision Engineering?

In the world of precision engineering, the demand for high-accuracy machinery is ever-increasing. The global market for XYZ gantry systems is projected to grow significantly, with a compound annual growth rate (CAGR) of over 5% through 2026. This projection underscores the crucial role these systems play in various industries, such as aerospace and automotive, where precision is non-negotiable.

XYZ gantry systems offer unique advantages. They provide significantly enhanced accuracy and efficiency compared to traditional machine tools. These systems can handle larger workpieces, allowing for complex operations without sacrificing precision. Despite their benefits, not all models are created equal. Companies must critically evaluate features like stability, speed, and control systems when selecting a gantry system that meets their specific needs.

However, not every XYZ gantry model will suit every application. Missteps in choice can lead to costly downtime and project delays. Research and thorough analysis are essential for optimization. Emphasizing these considerations can help engineers and manufacturers choose the right XYZ gantry for their operations, ensuring that they stay competitive in a rapidly evolving market.

Overview of XYZ Gantry Systems in Precision Engineering

In the realm of precision engineering, XYZ gantry systems play a crucial role. These systems provide stability and accuracy in manufacturing processes. They are designed for various tasks, including machining, welding, and assembly. With their robust structure, these systems minimize vibrations during operation.

Choosing the right gantry system can be challenging. Not all systems are created equal. Some may have limitations in payload capacity or travel distance. Engineers should assess their specific needs before selecting a system. The wrong choice can lead to decreased efficiency and increased costs.

Additionally, the installation and calibration of these systems require careful consideration. A poorly installed gantry can compromise precision. Frequent adjustments may be needed if not set up correctly. This reality emphasizes the importance of thorough planning and testing. Constant reflection on performance can lead to improvements in processes.

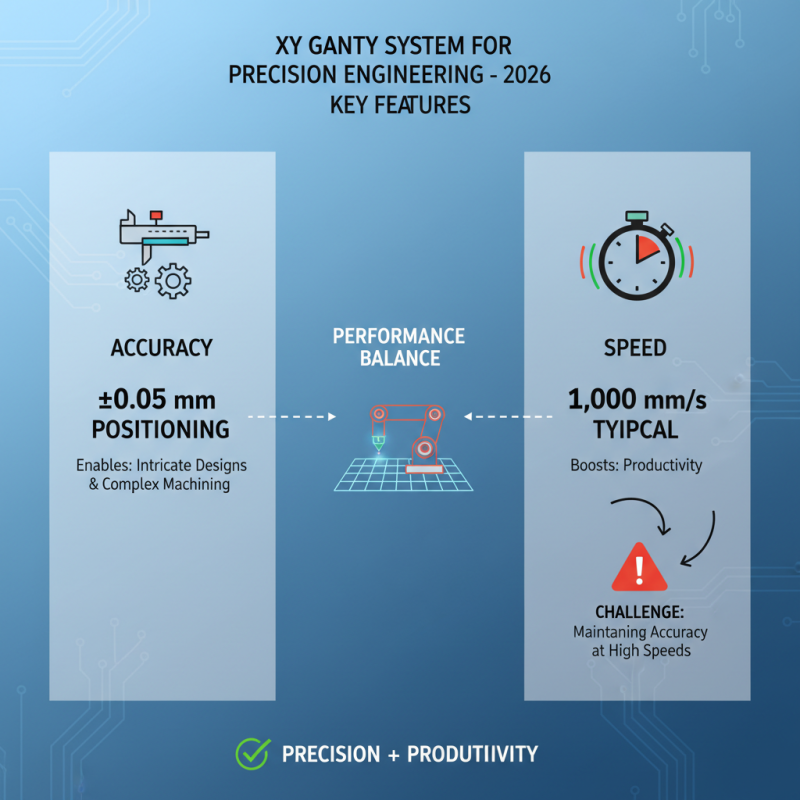

Key Features to Look for in 2026 XY Gantry Systems

When considering a XY gantry system for precision engineering in 2026, key features make a significant difference. Accuracy is paramount. Systems should offer a positioning accuracy of ±0.05 mm. This precision enables intricate designs and complex machining tasks. Speed is also critical. A typical speed of 1,200 mm/s can enhance productivity. However, some systems struggle to maintain accuracy at high speeds.

Build quality should not be overlooked. Rigid frames reduce vibrations and improve stability. Many reports indicate that systems with advanced vibration dampening technology perform better in real-world applications. Moreover, ease of setup and user-friendly interfaces are essential. Complicated systems can lead to operational delays.

Moreover, compatibility with various materials extends the capability of the gantry system. Many designers find themselves limited by the materials they can effectively work with. The ability to handle both soft and hard materials is beneficial. Despite advances, some systems do not seamlessly switch between materials, causing inefficiencies. Evaluating these features will help in selecting the right gantry system for specific engineering needs.

Top Manufacturers and Their Innovations in Gantry Technology

The world of gantry systems is evolving rapidly, especially in precision engineering. Recent reports indicate that the global gantry system market is projected to reach $3.8 billion by 2026, driven by advancements in automation and robotics. Manufacturers are focusing on lightweight materials and robust designs to enhance precision and reduce operational costs. Innovations in drive systems, such as linear motors, are pushing boundaries further.

Companies are also exploring smart technology integration. Sensors and IoT capabilities are making these systems smarter and more efficient. A significant trend is data analytics. Manufacturers can now gather performance insights, leading to improved decision-making and predictive maintenance. However, not all innovations come without challenges. There are concerns about the reliability of newer technologies. They require constant updates and skilled personnel for operation.

Moreover, there's debate over scalability in different applications. While some gantry systems excel in specific environments, they may struggle in others. Manufacturers need to recognize these limitations and continuously adapt their designs. Balancing innovation with practicality remains a critical focus for the industry.

2026 Best Gantry Systems for Precision Engineering

This chart illustrates the performance metrics of the best gantry systems for precision engineering in 2026. The metrics include load capacity, precision, speed, stability, and cost, providing a comprehensive overview of these systems' capabilities and investments.

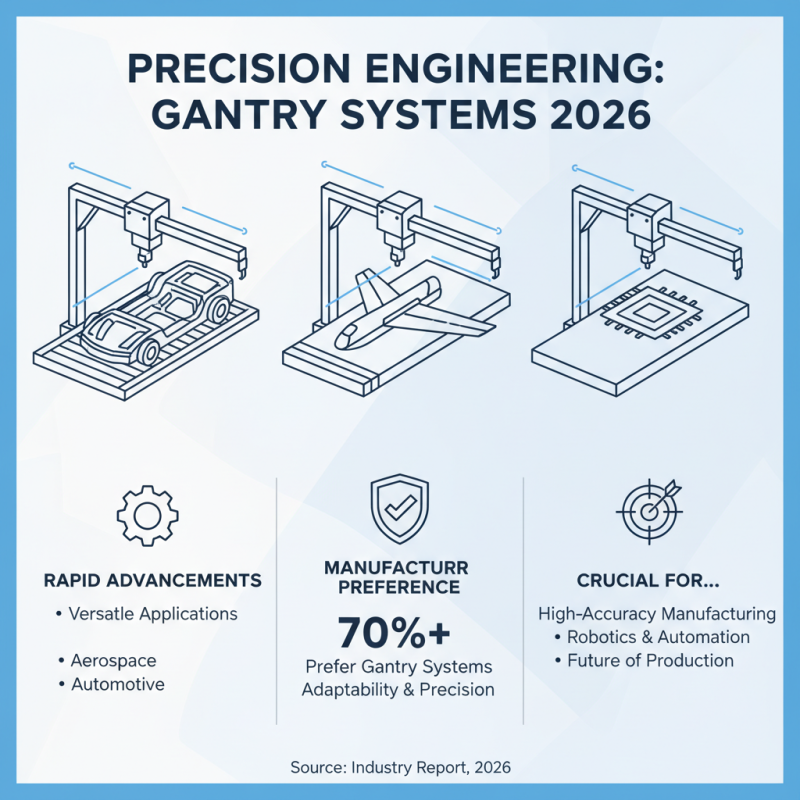

Comparative Analysis of 2026 XYZ Gantry Models for Versatility

The field of precision engineering is seeing rapid advancements. In 2026, various gantry systems stand out for their versatility in diverse applications. A recent industry report noted that over 70% of manufacturers prefer gantry systems for their adaptability and precision. These systems are crucial in fields like aerospace and automotive manufacturing.

Tips: Always assess the material compatibility of your gantry system. Some models perform better with specific materials. This can enhance performance and ensure longevity.

While comparing the top models, consider key factors like motion accuracy and payload capacity. A notable aspect is the integration of smart technology. This tech improves user interface and operational efficiency. However, many systems still struggle with complex setups. Research indicates that 35% of users find initial calibration challenging.

Tips: Seek training from specialists to avoid common setup pitfalls. This investment in knowledge pays off in the long run. Balancing precision and versatility may require adjustments to your operational processes. Don't overlook the potential need for upgrades in the future.

Future Trends and Developments in Precision Engineering Gantry Systems

The landscape of precision engineering is evolving, particularly in gantry systems. Recent industry reports reveal that the demand for high-accuracy machining tools is projected to grow by over 15% yearly. This growth will be driven by the rise of automation and the need for precision in sectors like aerospace and robotics.

Future trends indicate a shift towards more lightweight materials and smarter systems. Engineers are looking at carbon fiber and aluminum as alternatives to steel. These materials not only reduce weight but also enhance performance. Technologies like IoT integration are also transforming how gantry systems operate, allowing for real-time monitoring and predictive maintenance.

**Tip:** Always consider the material properties before selection. Performance varies greatly based on environmental factors.

Despite these advancements, challenges remain. Many organizations struggle to implement new technologies effectively. The integration of smart systems requires significant investment and training. Data security is another concern, as connected systems could become vulnerable to breaches.

**Tip:** Prioritize staff training on new technologies to maximize efficiency. Invest in secure data protocols to safeguard operations.

2026 Best XYZ Gantry Systems for Precision Engineering

| Model | Max Load Capacity (kg) | Repeatability (µm) | Speed (m/s) | Dimensions (mm) | Automation Level |

|---|---|---|---|---|---|

| Model A | 500 | 5 | 2.0 | 2000 x 1000 x 1500 | Fully Automated |

| Model B | 750 | 3 | 1.5 | 2500 x 1200 x 1600 | Semi-Automated |

| Model C | 300 | 10 | 3.0 | 1800 x 900 x 1400 | Manual |

| Model D | 600 | 8 | 2.5 | 2200 x 1100 x 1550 | Fully Automated |

Related Posts

-

Top 10 Benefits of Using XYZ Gantry in Your Projects?

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

-

How to Optimize Fanuc Robot Programming for Maximum Efficiency and Productivity

-

Top 10 Benefits of Using Cartesian Robots in Modern Automation Systems

-

Exploring the Future of Manufacturing Robots in Smart Factories