How to Choose the Best Automated Storage Systems for Your Business?

Choosing the right automated storage systems is crucial for business efficiency. Experts in the field emphasize the importance of making informed decisions. As John Smith, a renowned logistics consultant, stated, "Selecting the best automated storage systems is not just about technology; it's about understanding your unique needs."

In today's fast-paced market, businesses face growing demands for efficiency and accuracy in inventory management. Automated storage systems can streamline operations, but the choices can be overwhelming. Factors such as storage capacity, speed, and budget must be considered. A system that works for one company may not suit another's requirements.

Reflecting on the selection process, many businesses overlook their specific operational needs. They may choose a flashy system without ensuring it addresses their challenges. This can lead to wasted resources and missed opportunities. Understanding what an automated storage system can really offer is key to achieving long-term success.

Understanding Automated Storage Systems and Their Benefits

Automated storage systems revolutionize how businesses manage their inventory. These systems employ advanced technology to streamline storage processes. By integrating robotics and software, they enhance efficiency. Businesses can save valuable floor space and reduce labor costs. Imagine maximizing every inch of your warehouse with smart shelving units. This leads to a significant increase in productivity.

However, adopting these systems can pose challenges. The initial investment may be daunting for some businesses. Implementation requires training staff to interact with new technologies. Not all employees adapt quickly. Maintenance is another area of concern. Systems can encounter malfunctions, leading to potential downtime. Therefore, a thorough understanding of the capabilities and limitations is crucial.

Embracing automated storage can be a double-edged sword. While it maximizes efficiency, it also demands a shift in company culture. Employees may feel apprehensive about job security. Transparency and training are essential in addressing these issues. Ultimately, a balanced approach can lead to successful integration and improved operations.

How to Choose the Best Automated Storage Systems for Your Business?

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Space Utilization | Maximizes storage area efficiently. | Reduces footprint, saves costs. | Initial investment can be high. |

| Automation Level | Varies from semi-automated to fully automated systems. | Improves speed and efficiency. | Need for employee trainig. |

| Integration | Compatibility with existing systems. | Streamlines operations. | May require software updates. |

| Cost | Initial set-up cost and ongoing maintenance. | Long-term savings on labor and space. | Budgeting for unexpected costs. |

| Scalability | Ability to expand as business grows. | Future-proofs your investment. | Needs assessment for future demands. |

Identifying Your Business Needs for Storage Solutions

When evaluating storage solutions, start by identifying your specific needs. What items are you storing? Are they small parts, large equipment, or seasonal inventory? Knowing the size and type of goods is crucial. If you overlook this step, you may end up with an inadequate system.

Consider your workflow. How often do you access these items? If your inventory turns over quickly, you need a system that facilitates easy access. Alternatively, if your items are seldom used, you may prioritize maximizing space instead. A mismatch in this aspect can lead to inefficiency.

Don’t forget about scalability. As your business grows, your storage needs will evolve. Choose a system that can adjust accordingly. Underestimating future demands could result in costly upgrades later. Reflections on your current operations can guide this decision. What challenges do you face now? Use those insights to shape your storage strategy.

Key Features to Consider in Automated Storage Systems

When selecting automated storage systems for your business, consider key features that align with your operational needs. Look for scalability in your chosen system. This allows your storage capacity to grow without significant changes to infrastructure. Systems that adapt to increasing inventory are essential in today’s fast-paced market.

Another critical aspect is the speed of retrieval. Fast retrieval minimizes downtime and enhances efficiency. Evaluate different retrieval mechanisms, such as shuttles or robotic arms, to find the best fit. User interface also matters. A simple interface promotes effective training and reduces errors. Systems that are difficult to learn can lead to frustration and operational delays.

Don't overlook maintenance requirements. Some systems need frequent servicing, impacting long-term costs. Think about your team’s ability to manage the system. A complex system may require additional staff training and extended onboarding. Take time to assess these factors. Mistakes made in the selection process can lead to wasted resources and inefficiencies down the road.

Key Features to Consider in Automated Storage Systems

Evaluating Costs and ROI of Automated Storage Solutions

When evaluating the costs of automated storage solutions, businesses must consider multiple factors. Initial investment plays a significant role. Some systems require substantial upfront capital. Others may offer leasing options, reducing immediate financial pressure. However, ongoing maintenance costs can accumulate quickly. It’s essential to budget for these expenses to avoid surprises later.

Return on investment (ROI) is vital for decision-making. Estimate how much time and labor automation saves. Track how efficiency improves and waste decreases. Quantifying these benefits can clarify the value of your investment. Some businesses see a significant return, while others may struggle. It’s crucial to assess your unique circumstances. Comparing potential output gains against costs will provide clearer insights.

Also, consider operational scalability. As demand changes, can the system adapt? If your business grows, will the storage solution keep pace? A less flexible system could limit future expansion. Reflecting on these points can reveal potential challenges. Balancing costs against both tangible and intangible benefits requires careful thought.

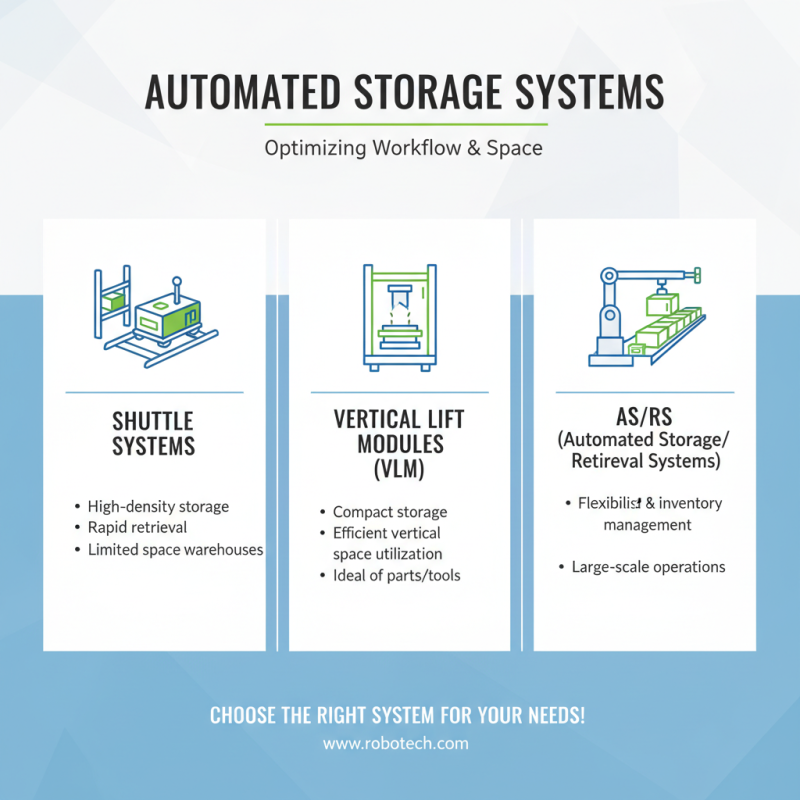

Comparing Different Types of Automated Storage Systems

When considering automated storage systems, various types come into play. There are shuttle systems, vertical lift modules, and automated storage/retrieval systems (AS/RS). Each type serves a unique purpose and can significantly impact your workflow. Shuttle systems excel in high-density storage and rapid retrieval, making them suitable for warehouses with limited space. Vertical lift modules offer compact storage and utilize vertical space efficiently. AS/RS systems provide flexibility and can enhance inventory management.

Evaluating these options can be complex. A company may need a system that fits specific needs, such as volume and speed. For instance, while a shuttle system may optimize space, its setup costs can be high. Alternatively, vertical lift modules might be more affordable but could lack speed. Sometimes, businesses rush into choosing based on surface benefits without fully grasping their operational requirements. It is crucial to review employee workflows and inventory turnover rates.

Take the time to assess your existing processes. The right automated storage system should align closely with your goals. Look for solutions that can grow with your business. Conduct trials or seek expert consultations to ensure you make an informed choice. Balancing cost and efficiency is challenging. Regularly revisit your decisions to adapt to changing needs. This reflective approach can lead to better long-term outcomes.

Related Posts

-

Why Is Automated Storage Essential for Modern Businesses?

-

Understanding ASRS System Warehouse: Transform Your Storage Efficiency Today!

-

What is Automated Storage and How Does it Benefit Your Business

-

10 Best Automated Storage Solutions for Efficient Space Management

-

2026 Best Automated Material Handling Solutions for Efficient Warehousing?

-

Top 5 Benefits of ASRS Warehouse Systems for Modern Logistics?