2026 How to Choose the Best Industrial Robot Arm for Your Business?

In the rapidly evolving world of automation, choosing the right industrial robot arm is crucial for business success. Experts like Dr. Emily Richards, a leading authority in robotics, emphasize, "Selecting the right robot is essential to optimize productivity." Her insight highlights the importance of informed decisions when adding new technology to operations.

Many businesses face a daunting task when evaluating various industrial robot arms. Each model offers unique features and capabilities. However, not every option will suit every need. Factors like payload capacity, reach, and precision must align with specific operational requirements. This complexity can lead to confusion and second-guessing in decision-making.

Additionally, many companies struggle with the integration of these robots into existing workflows. This can result in inefficient setups and wasted resources. Reflecting on the nuances of your operations is key. Understanding both the potential and limitations of an industrial robot arm is essential for maximizing its benefits. Exploring expert insights and real-world applications can guide you through this complex selection process.

Understanding Your Business Needs for Industrial Robot Arms

Choosing the right industrial robot arm for your business starts with understanding your specific needs. Different industries require different solutions. For example, automotive manufacturing often focuses on high precision and speed, while food packaging may prioritize hygiene and flexibility. According to a report by Mordor Intelligence, the industrial robotics market is expected to grow at a CAGR of 14.5% from 2021 to 2026. This suggests a strong increase in demand, making the right choice critical.

Consider your production volume and product types. If you operate in a high-mix environment with varying products, a versatile robot arm may be essential. In contrast, a dedicated robot might be more suitable for high-volume tasks. This flexibility will influence the robot’s configuration, payload capacity, and reach. Additionally, assess the skill level of your workforce. A complex system may require extensive training, potentially causing downtime.

Reflect on your potential return on investment (ROI). Investing in a robot arm is significant, and the wrong choice could lead to wasted resources. According to the International Federation of Robotics, up to 20% of companies report underutilization of their robotic systems. Understanding potential constraints and possible inefficiencies is key. Make sure to conduct a thorough needs assessment before making a decision.

Comparison of Key Factors for Choosing Industrial Robot Arms

Analyzing Key Specifications: Payload, Reach, and Precision Metrics

Choosing the right industrial robot arm involves careful consideration of key specifications. Payload capacity is crucial. It determines how much weight the robot can handle. It’s vital for tasks like lifting heavy parts. A robot with insufficient payload may fail in demanding environments. Understanding your operational needs here is essential.

Reach is another important metric. This refers to how far the robot can extend its arm. It directly impacts the workspace design. If the reach is too limited, the robot may not be able to access vital areas. Proper analysis of your facility layout will help optimize the arm's effectiveness.

Precision is about accuracy in task execution. This metric becomes critical in assembly and welding tasks. Even small errors can cause significant setbacks. Reflecting on the required precision for each application allows for better choices. Complex tasks may demand higher precision levels. Balancing these specifications against budget constraints can be challenging. Decisions may need revisiting as needs evolve.

Evaluating Different Types of Industrial Robot Arms by Application

When selecting an industrial robot arm, it's crucial to assess the specific applications your business requires. Various types of robot arms cater to different tasks. For simple pick-and-place jobs, a delta robot might be ideal due to its speed and precision. If your focus is on welding or assembly, a articulated robot could offer the flexibility needed for complex movements.

Consider the weight capacity as well. Some arms handle heavy payloads, while others excel in lighter tasks. When choosing, think about workspace limitations. Some robotic arms need more room to operate effectively. This could lead to inefficiencies if not addressed early in the planning process.

Evaluate your current workflow. Are there repetitive tasks that could be automated? Robots can enhance productivity but require upfront investment and training. Reflect on whether your workforce is ready to adapt. An improper integration can disrupt operations and lead to frustration. Each choice demands careful thought and realistic expectations. Be prepared to assess your needs consistently.

2026 How to Choose the Best Industrial Robot Arm for Your Business?

| Type of Robot Arm | Payload Capacity (kg) | Reach (mm) | Application | Key Features |

|---|---|---|---|---|

| SCARA | 10 | 500 | Assembly, Picking | High speed, Compact design |

| Articulated | 200 | 1500 | Welding, Painting | Flexibility, High degrees of freedom |

| Delta | 5 | 800 | Packaging, Sorting | High speed, Lightweight design |

| Cartesian | 30 | 1000 | Material handling, CNC | Simplicity, Cost-effective |

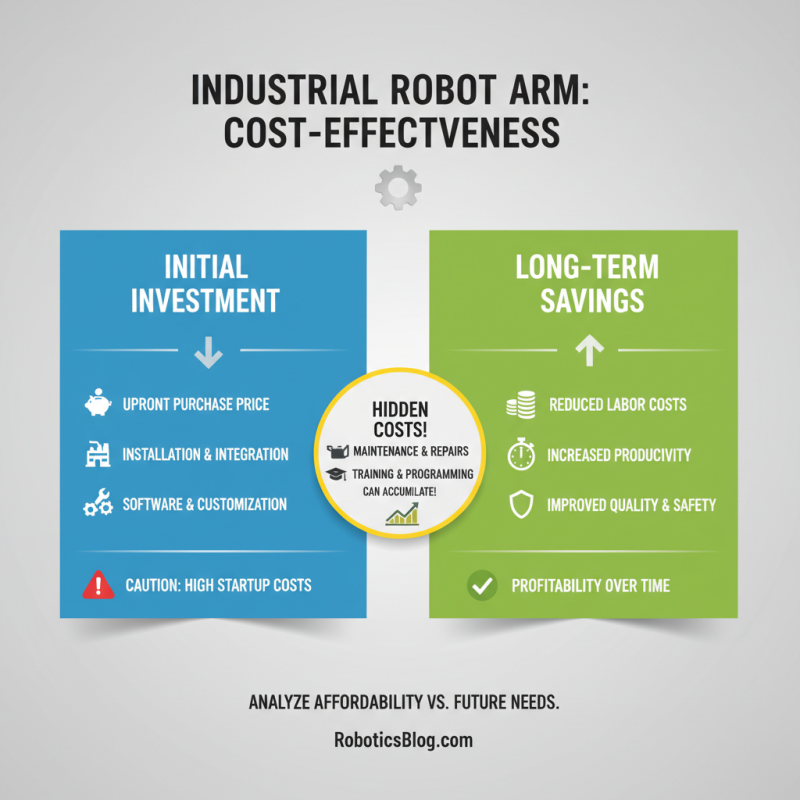

Assessing Cost-Effectiveness: Initial Investment vs. Long-Term Savings

When assessing cost-effectiveness in industrial robot arms, initial investment and long-term savings are critical factors. The upfront costs can be significant, even daunting for some businesses. It's essential to analyze what you can afford at the start while keeping future needs in mind. Sometimes, businesses underestimate hidden costs, such as maintenance and training. These can accumulate more than anticipated.

In the long run, a more expensive robot could save you money. With greater efficiency and lower downtime, you may find savings that offset the initial price. Consider operating costs too. Energy consumption varies dramatically among models. You might invest less now but pay higher utility bills later. A detailed comparison helps illuminate these factors.

It’s also vital to account for potential growth. A robot that suits current needs may quickly become inadequate. Reflect on scalability and versatility. A more adaptable arm might seem costly initially but can evolve with your business. It's a balancing act between immediate budget constraints and future readiness.

Integrating Robots into Existing Workflows: Challenges and Solutions

Integrating industrial robots into existing workflows presents unique challenges. According to a recent industry report, nearly 70% of companies face integration issues due to legacy systems. These challenges often arise from incompatible software and hardware setups. Training is another major hurdle. Employees may find it difficult to adapt to new robotic systems. Often, they require extensive training to use them efficiently.

Tips: Assess your current workflow. Identify areas where robots can help, but also consider where disruptions might occur. Communication with staff is vital. Ensure everyone understands the benefits and expectations of this integration.

Implementation can reveal unintended obstacles. Many businesses underestimate the time required for proper setup. A 2023 survey indicates that 40% of robotics projects exceed their initial timelines. Be prepared to iterate and adapt your approach as problems arise. Flexibility can lead to better solutions in the long run. Monitoring systems continuously is essential for success.

Tips: Start small. Test robotic arms in limited applications before broader deployment. Collect feedback from users on the ground. This insight can significantly enhance efficiency and reduce resistance to change.

Related Posts

-

How to Choose the Right Industrial Robot Arm for Your Needs?

-

What is Industrial Robotics and How Does it Transform Manufacturing?

-

Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

How to Choose the Right Manufacturing Robots for Your Production Needs