How to Choose the Right Industrial Robot Arm for Your Needs?

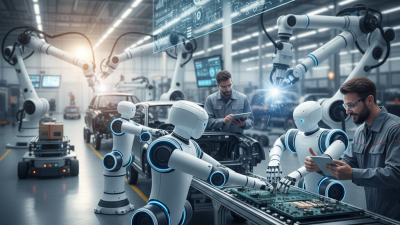

Choosing the right industrial robot arm is crucial for optimizing production efficiency. As John Smith, an expert in automation technology, states, “The right robot makes all the difference.” Understanding specific needs can simplify the selection process.

Industrial robot arms come in various types and configurations. Each is designed for different tasks, such as welding, painting, or assembly. It’s vital to identify your unique requirements. For instance, consider payload capacity, reach, and precision. The wrong choice can lead to inefficiencies and frustration.

In the ever-evolving world of manufacturing, the perfect robot arm doesn't always exist. Potential buyers often face challenges in aligning technology with real-world applications. After all, flexibility and adaptability are essential. Taking the time to reflect on specific needs can lead to better decisions.

Understanding the Different Types of Industrial Robot Arms

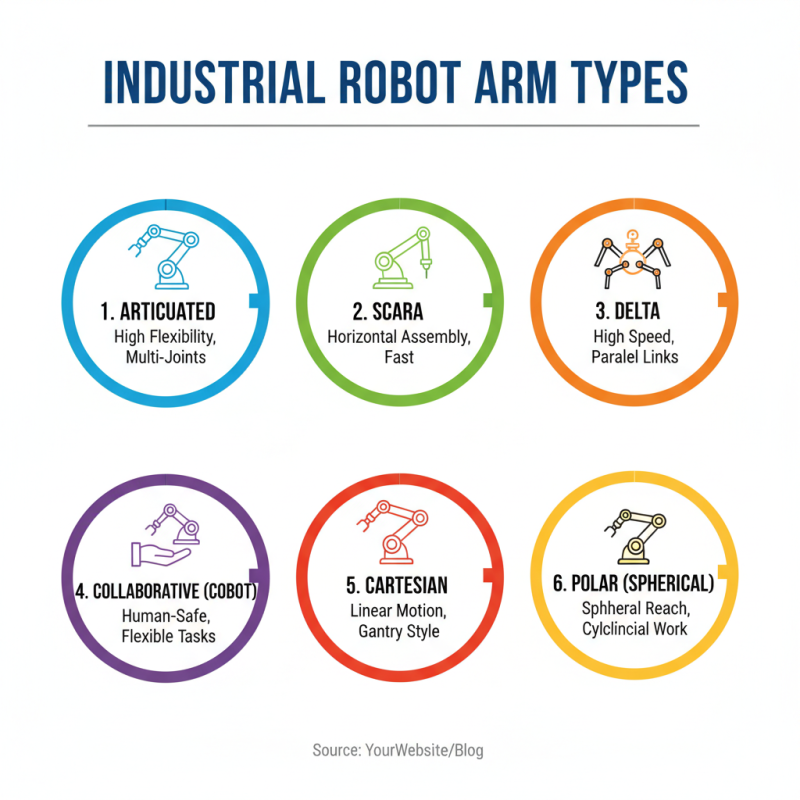

When selecting an industrial robot arm, understanding its types is crucial. There are six primary types: articulated, SCARA, delta, collaborative, Cartesian, and polar. Each type serves different needs. Articulated arms offer flexibility with their multiple joints. SCARA robots excel in horizontal movements, ideal for assembly tasks. Collaborative robots, or cobots, work alongside humans, enhancing safety and productivity.

Recent industry reports highlight that articulated robots account for over 50% of robot sales, reflecting their versatility. Delta robots, known for speed, work best in packaging and sorting applications. They can achieve cycle times as low as 0.5 seconds. However, their setup can be complex, requiring skilled technicians.

On the other hand, Cartesian robots are straightforward and accurate, often used in CNC applications. While they have simpler control systems, their scope can be limited compared to articulated arms. It's essential to assess your specific requirements and workflow. Balancing speed, complexity, and cost is vital. Some companies overlook these factors, leading to inefficiencies. Understanding the unique aspects of each type can significantly impact your operations.

Assessing Your Specific Application Requirements

Choosing the right industrial robot arm begins with assessing your specific application requirements. Consider the tasks involved. Are you handling assembly, welding, or painting? Identifying the primary function will help narrow down options. The payload capacity is crucial. Different robots can lift varying weights. Ensure the robot can handle your heaviest components.

Speed and precision are also vital factors. A fast robot may not always be the best choice if accuracy suffers. Think about your production goals. Is speed your priority, or is meticulous precision more important? It’s a balancing act that requires thoughtful analysis. Some industries demand high precision, while others thrive on speed.

Don’t overlook your workspace constraints. A robot that’s too large may not fit on your production floor. Craft flexibility into your planning. You might need adjustments later. Evaluate maintenance requirements as well. Some robots require frequent upkeep, which could hinder productivity. Reflect on how much time your team can dedicate to maintenance tasks.

Evaluating Key Specifications and Features

When selecting an industrial robot arm, evaluating key specifications is crucial. Payload capacity is a primary consideration. Most robot arms can handle between 5 to 1,000 kg. This variation depends on the application. For example, lighter arms often excel in assembly tasks, while heavier models are ideal for material handling.

Another important feature is reach. Robot arms typically have a reach between 500 mm and 3,000 mm. A larger reach allows for more versatility in operation. However, it can also complicate the setup and integration process. Understanding your workspace dimensions is vital here. A miscalculation can lead to inefficient workflows.

Speed and precision are equally important. Some robots can perform cycles in under a second, while others may take several seconds. Precision is measured in millimeters, with high-end arms achieving +/- 0.02 mm accuracy. Notably, over 50% of manufacturers report encountering difficulties with the accuracy of their chosen arms. Thus, assessing your specific needs and limitations helps avoid costly mistakes.

Industrial Robot Arm Specifications Comparison

This chart compares key specifications of a hypothetical industrial robot arm model. The data represents payload capacity, maximum reach, repeatability, and degrees of freedom, which are critical factors in selecting the right robot arm for your needs.

Comparing Costs and Budget Constraints

When selecting an industrial robot arm, costs often play a pivotal role. Many manufacturers seek to optimize their budget while ensuring efficiency. The initial investment can vary significantly, depending on the arm’s capabilities, payload, and precision. Customizable options may attract higher initial costs, but they can lead to long-term savings. Sometimes, cheaper models seem appealing, but they may not deliver the expected performance.

Consider ongoing expenses too. Maintenance and operational costs can add up. For instance, a low-cost robot might need frequent repairs. This can lead to hidden costs that outweigh the initial savings. Getting a comprehensive quote is essential. Evaluate all potential costs, including training and integration.

Reflecting on specific needs is crucial. A robot arm should fit well with your production process. Over-specifying can lead to unnecessary expenses, while underestimating needs can result in inefficiencies. Misalignment between the robot's capabilities and your requirements can cause issues. Therefore, an honest assessment of your production goals is necessary to make the right choice. Aim for a balance between capability and budget to achieve the best outcome.

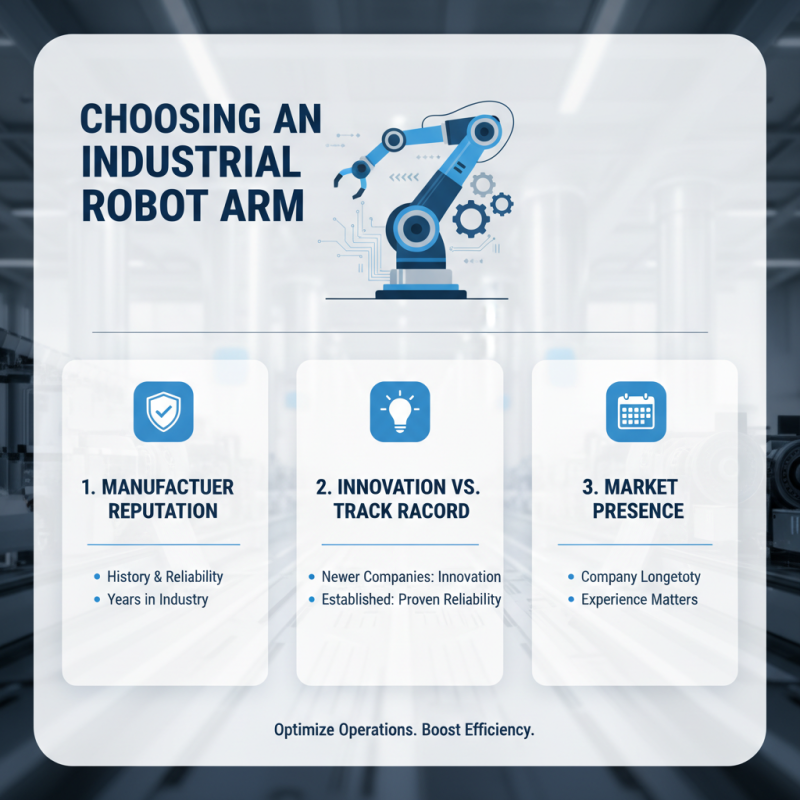

Researching Manufacturer Reputation and Support Services

Choosing the right industrial robot arm is crucial for optimizing your operations. One major factor is the manufacturer's reputation. Researching the history of the manufacturer can provide insights into their reliability. Look for companies with years of experience in the industry. Newer companies might not have the same track record, but they can offer innovation. Always consider how long they have been in the market.

Support services also play a vital role. Consider the availability of technical support after purchase. A company that offers 24/7 support can be a lifesaver. Response time is critical when issues arise. If they recommend a service plan, weigh its value against your needs. Frequent downtime can be costly, so understanding service options is key.

Read customer reviews and testimonials. They provide a real-world perspective on the manufacturer's performance. However, not all reviews are positive. Some might reflect isolated incidents, while others can indicate systemic issues. Trying to communicate with current users can fill gaps in your research. A personal touch can often reveal hidden strengths or weaknesses of the manufacturer.

Related Posts

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity

-

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

-

Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing