How to Choose the Right Gantry Robot for Your Automation Needs

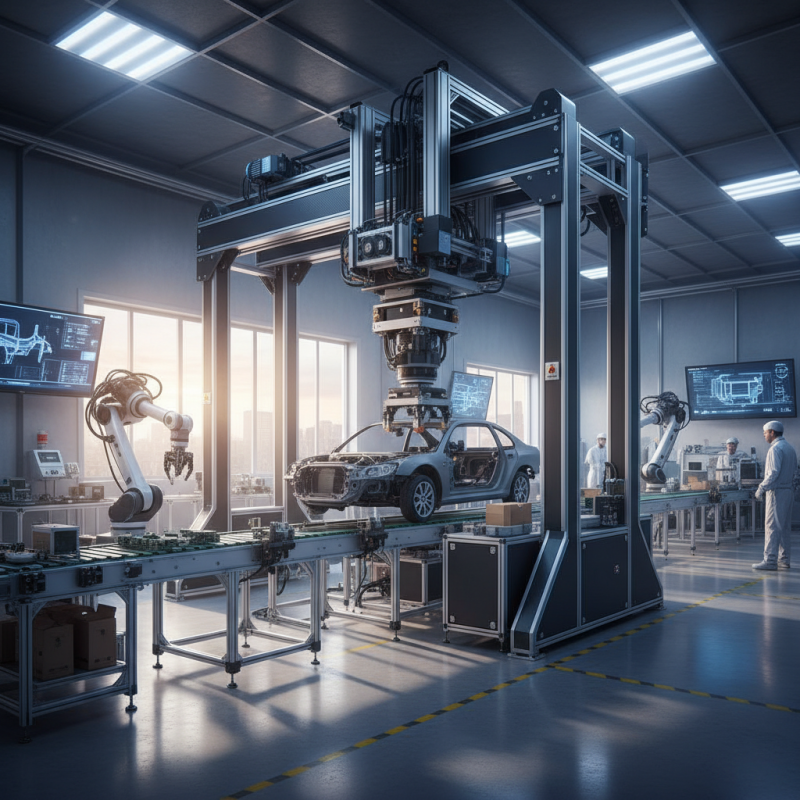

In today's rapidly evolving manufacturing landscape, the importance of automation cannot be overstated. Gantry robots, known for their versatility and precision, play a pivotal role in streamlining production processes across various industries. A recent report from the International Federation of Robotics highlights that the adoption of gantry robots has increased by over 30% in sectors such as automotive and electronics, signaling a significant shift towards automation. These robots provide not only operational efficiency but also enhanced quality control, proving essential for competitive advantage in the marketplace.

To ensure optimal performance and meet specific automation needs, choosing the right gantry robot is crucial. "The key to successful automation is understanding the unique requirements of your operations and aligning them with the capabilities of the gantry robot you select," remarks Dr. Emily Tran, a leading expert in robotic automation. Her assertion emphasizes the importance of a tailored approach that considers factors like payload capacity, workspace dimensions, and integration capabilities. In a world where precision and efficiency dictate success, making informed decisions about gantry robots can pave the way for transformative advancements in productivity and innovation.

Understanding Gantry Robots: Types and Applications

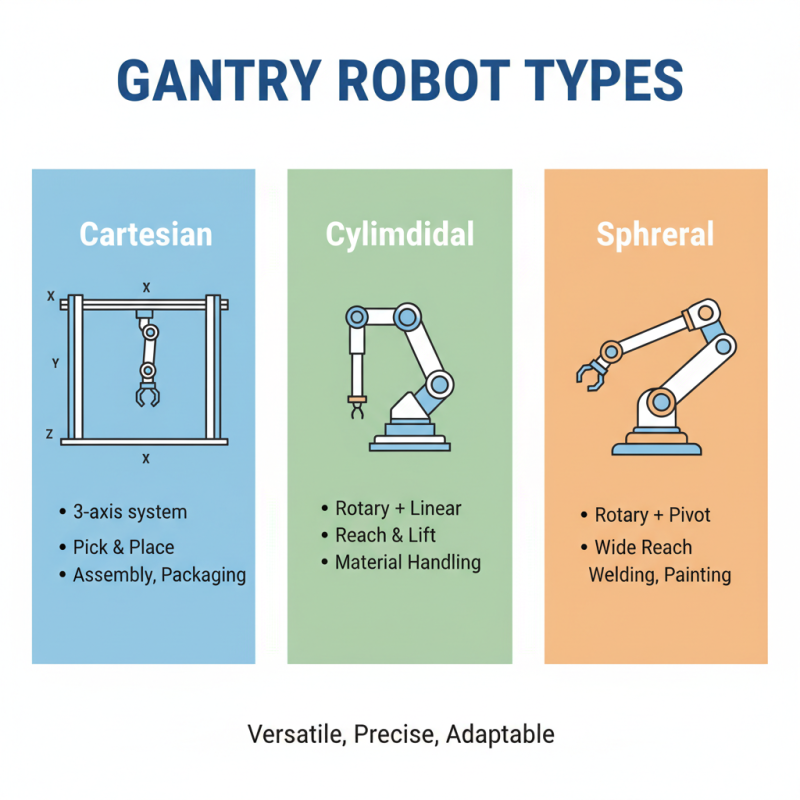

Gantry robots, known for their versatility and precision, are available in various types, each tailored for specific applications. The most common types include Cartesian, cylindrical, and spherical gantry robots. Cartesian gantry robots operate on a three-axis system, making them ideal for pick-and-place operations in assembly lines. Their straightforward design allows for easy integration into existing workflows, offering flexibility for tasks such as material handling and packaging.

Cylindrical gantry robots, on the other hand, incorporate a rotary axis, which grants them a wider range of motion. These robots are well-suited for applications that require a larger working envelope, such as welding and painting, where precision and reach are critical. Spherical gantry robots, featuring a unique design with rotational joints, excel in environments where overhead space is limited. They provide flexibility while allowing for complex movements, making them ideal for intricate assembly tasks or quality inspections. Each type of gantry robot brings distinct advantages, making it essential to choose the right one based on your specific automation requirements and space constraints.

Key Factors to Consider When Choosing a Gantry Robot

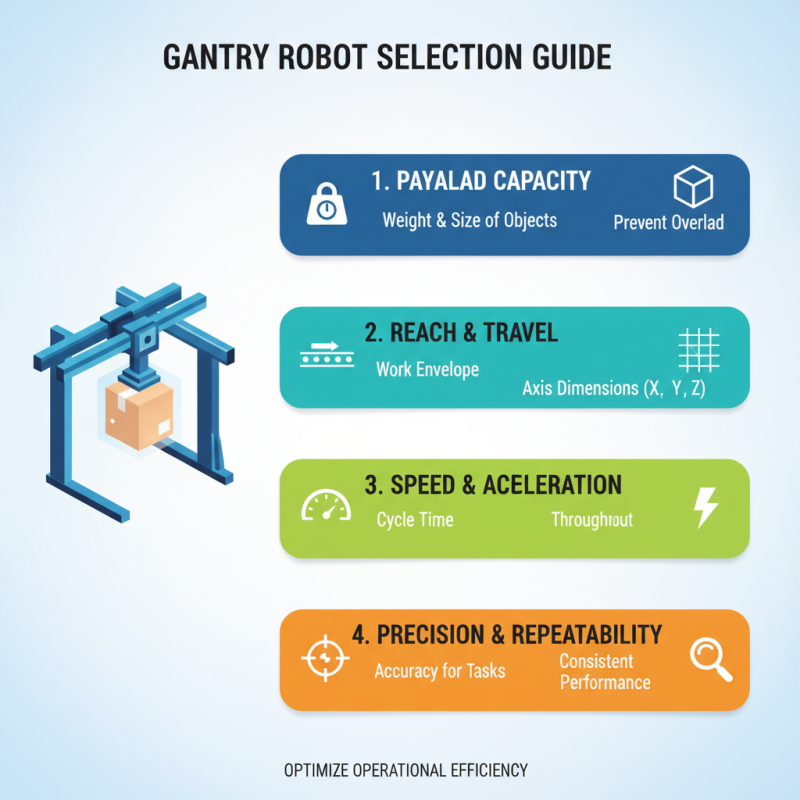

Choosing the right gantry robot for your automation needs involves evaluating several key factors that can significantly impact your operational efficiency. First, consider the payload capacity of the gantry robot. It's essential to determine the weight and dimensions of the objects it will handle. Selecting a robot with adequate capacity ensures optimal productivity and prevents potential overloads that can lead to equipment failure.

Another crucial factor is the robot's reach and workspace. Assess the area where the robot will be deployed and ensure that its reach aligns with your production layout. If your tasks involve multiple workstations, a gantry robot with a longer reach could enhance workflow efficiency by minimizing the need for repositioning.

**Tips**: When evaluating these factors, compile a list of your operational requirements. Engage stakeholders in discussions to understand the specific tasks the robot will perform. This can lead to a clearer picture of the robot specifications needed.

Lastly, don't overlook the importance of ease of integration. The compatibility of the gantry robot with existing systems and automation platforms can save time and reduce costs during implementation. Evaluate the robot's programming capabilities and user interface to ensure it aligns with your team’s skill set and operational goals.

**Tips**: Conduct thorough research on different automation technologies and ask for demonstrations if possible. Understanding the functionalities will help you make a more informed decision tailored to your workflow demands.

Evaluating Load Capacity and Range of Motion

When choosing the right gantry robot for your automation needs, evaluating the load capacity and range of motion is crucial. Load capacity refers to the maximum weight a robot can handle safely and efficiently. According to a report by the International Federation of Robotics (IFR), industrial robots are increasingly designed to accommodate heavier payloads, with many models offering capacities exceeding 1,000 kg. Understanding the specific load requirements of your operations is essential, as underestimating this factor can lead to inefficiencies or equipment failure.

In addition to load capacity, the range of motion is a significant aspect of gantry robots that influences their versatility and application scope. Most gantry robots operate within a specified range, usually described in three dimensions: horizontal, vertical, and rotational. As per the 2022 World Robotics Report, advancements in motion control technology have expanded the capabilities of these systems, allowing for greater reach and flexibility. For instance, some systems now offer linear motion ranges greater than 10 meters, enabling them to handle large workspaces and complex tasks. Evaluating both load capacity and range of motion helps ensure that a chosen gantry robot aligns with your operational efficiency and production goals.

Assessing Software and Integration Compatibility

When selecting a gantry robot for automation needs, assessing software and integration compatibility is crucial to ensure seamless operation within your existing system. First, evaluate the software capabilities of the gantry robot. Determine whether it supports common programming languages and control methods relevant to your application. The choice of software will affect how easily your team can program and operate the robot, as well as how well it can adapt to future changes or upgrades in technology. Ensure the robot's software offers user-friendly interfaces and comprehensive documentation to facilitate smoother onboarding and training processes.

Integration compatibility is another key factor when choosing a gantry robot. Analyze how the robot will interact with your current machinery, sensors, and other automation systems. Check for compatibility with existing communication protocols such as Ethernet/IP, Modbus, or PROFIBUS, which are essential for enabling data exchange and orchestrating tasks between devices. You might also want to consider the availability of APIs or middleware solutions that can bridge gaps between different systems, thereby enhancing overall functionality. A thorough assessment of these aspects will help ensure that your gantry robot can be integrated effectively, maximizing its performance and return on investment over time.

Maintenance and Support for Gantry Robot Systems

When selecting a gantry robot for automation needs, maintenance and support are critical aspects that should not be overlooked. According to a report by the International Federation of Robotics, effective maintenance strategies can reduce downtime by an impressive 20-30%. Regular maintenance not only extends the lifespan of the gantry robot systems but also enhances performance, ultimately leading to increased productivity. A comprehensive maintenance plan should include routine inspections, adjustments, and updates, ensuring the machinery operates at peak efficiency.

Moreover, support plays a vital role in minimizing disruptions in operations. Many companies may opt for service contracts that provide 24/7 technical support and emergency services, which can significantly reduce the duration of any unforeseen breakdowns. Industry data suggests that having a dedicated support team can diminish response times by more than 40%, enabling quicker resolutions and minimizing the impact on production schedules. By investing in reliable maintenance and support frameworks, businesses can ensure their gantry robots contribute positively to their overall automation efforts, enhancing both operational efficiency and cost-effectiveness in the long run.

Gantry Robot Selection and Support Overview

Related Posts

-

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

-

How to Choose the Right Pick and Place Robot for Your Automation Needs

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

What is Automated Storage and How Does it Benefit Your Business

-

What is a Manufacturing Robot and How It Revolutionizes Modern Industries

-

Top 10 Fanuc Robot Applications in Manufacturing and Automation Industry