How to Choose the Right Industrial Robot Arm for Your Business?

Choosing the right industrial robot arm for your business is crucial. It impacts productivity, efficiency, and overall performance. With numerous options available, making a decision can feel overwhelming.

Every business has unique needs. Consider the specific tasks you want to automate. Different industrial robot arms excel in varied applications, from welding to packaging. Do you require precision or speed? What is your budget?

It’s essential to weigh the strengths and weaknesses of each model. Some may offer advanced features but come with higher costs. Others might be more affordable yet lack essential capabilities. Evaluate your, often limited, resources carefully. Understanding your requirements is key. Be prepared for a challenge, as this decision can shape your operational success.

Understanding Your Business Needs and Requirements

Choosing the right industrial robot arm requires a deep understanding of your business needs. Start by assessing your specific goals. How do you intend to use the robot? Will it handle assembly, painting, or packaging? Clarifying these purposes is essential.

Consider your production volume. High-output operations may need faster robots. Slower, more precise tasks might benefit from different arm types. Think about your workspace too. Is there enough room for the robot to move freely? Make sure to measure dimensions carefully. This can affect workflows significantly.

Don’t forget about employee safety and training. Robots should integrate smoothly with your team. If your staff lacks training, productivity might suffer. This transition can create tension, so plan accordingly. Reflect on these factors before making any decisions. Taking time to analyze them will lead to better outcomes.

Identifying the Types of Industrial Robot Arms Available

When selecting an industrial robot arm, understanding the types available is crucial. There are several categories, such as articulated, SCARA, and delta robots. Articulated arms resemble a human arm. They are versatile and can perform complex movements. SCARA robots excel in horizontal movements, making them ideal for assembly tasks. Delta robots, on the other hand, are designed for rapid movements in a limited space. Their structure allows for high-speed operations.

Choosing the right type involves assessing your specific needs. How many axes of movement do you require? Will the robot be handling heavy items or delicate components? These factors can narrow down your options. The choice also depends on your workspace layout. A large area might accommodate an articulated arm. However, a compact environment may benefit from a delta robot.

One might feel overwhelmed by the options available. Each type of robot arm offers unique advantages. Yet, finding the perfect fit can be challenging. It is essential to reflect on the tasks at hand. Are you maximizing efficiency with your current setup? Sometimes, a simple robot is all you need. Don’t hesitate to seek expert advice to better navigate this decision.

Comparison of Different Types of Industrial Robot Arms

Evaluating Technical Specifications of Robot Arms

When selecting an industrial robot arm, technical specifications play a vital role. The payload capacity is crucial; it determines how much weight the arm can handle. Evaluate the arm's reach, as it affects how far it can operate. A robot with limited reach may not fit larger workspaces. The degrees of freedom are essential too. More joints mean greater flexibility and a wider range of motion.

Speed and precision are important metrics. Some applications require fast, accurate movements, while others may prioritize strength. Look into the repeatability of the robot arm. A variance in movements can lead to production inconsistencies. Cost is also a factor but shouldn't be the only consideration. Cheaper models may compromise on quality and longevity.

Consider the ease of integration. How well will the robot arm fit into your existing systems? A complicated setup can hinder productivity. Flexibility in programming is also essential. Some arms are more user-friendly than others. Evaluate your team's skill level. Ensure they can operate and troubleshoot the system effectively. This can save time and reduce stress in the workplace.

Considering Budget and Cost-effectiveness for Your Investment

When investing in industrial robot arms, budget and cost-effectiveness are crucial. Research shows that companies can save up to 30% in operational costs with the right automation. However, the initial purchase price can vary widely. Choosing a robot arm should involve a thorough analysis of your specific needs and financial constraints.

Tips: Assess your production volume. Higher volumes may justify higher upfront costs. Calculate the return on investment (ROI). This can illuminate long-term savings versus immediate expenses.

Not all industrial robot arms are the same. Some may offer advanced features but come with higher costs. Others might be simple but effective. Balancing features with your budget is essential. Flexibility is also vital. For example, a modular approach could lead to future scalability, which saves money later.

Remember, this investment requires ongoing evaluation. Maintenance and additional training can add to costs. Approximately 20% of budgets are used for training staff on new technology. It is critical to consider these ongoing costs when making your decision. The right choice will optimize productivity and efficiency in the long run.

How to Choose the Right Industrial Robot Arm for Your Business? - Considering Budget and Cost-effectiveness for Your Investment

| Robot Arm Type | Cost (USD) | Payload Capacity (kg) | Reach (mm) | Energy Consumption (kWh) | Programming Ease |

|---|---|---|---|---|---|

| Articulated Arm | $50,000 | 10 | 1200 | 2.5 | Moderate |

| Cartesian Arm | 30,000 | 5 | 1500 | 1.8 | Easy |

| Delta Robot | 40,000 | 3 | 800 | 2.0 | Moderate |

| SCARA Robot | 35,000 | 7 | 1000 | 1.5 | Easy |

| Collaborative Robot (Cobot) | 25,000 | 4 | 1300 | 1.2 | Easy |

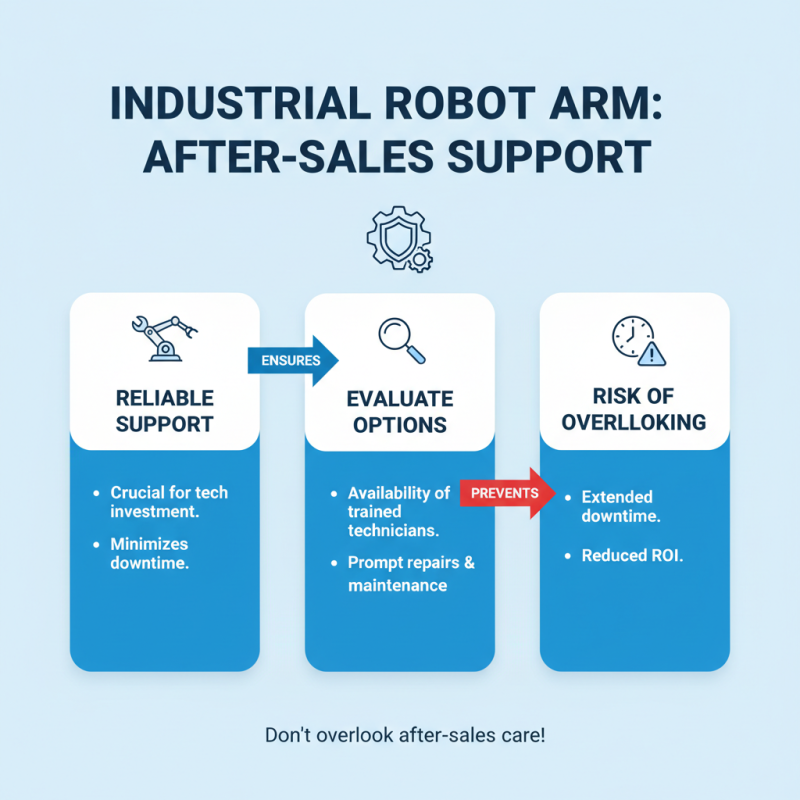

Analyzing After-sales Support and Maintenance Options

When selecting an industrial robot arm, after-sales support and maintenance options are crucial. You need reliable support for the technology you invest in. Evaluate the availability of trained technicians for repairs and maintenance. Many businesses overlook this aspect, which can lead to extended downtime.

Regular maintenance schedules are essential. Some suppliers offer comprehensive service packages, while others do not. Understand what's included—regular check-ups, spare parts availability, or emergency repairs. These details matter. A lack of support may render your investment ineffective.

Consider the accessibility of technical documentation and online resources. Some manufacturers offer extensive documentation and tutorials, aiding in troubleshooting. In contrast, others provide minimal resources. This difference can impact your operational efficiency. Think about your team’s ability to handle minor issues themselves. Investing in a robot arm without considering support options can lead to regret later on.

Related Posts

-

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today

-

2025 How to Choose the Best Machine Tending Robot for Your Business Needs

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

How to Choose the Right Pick and Place Robot for Your Automation Needs

-

How to Efficiently Use XYZ Gantry for Your Next Project Guide