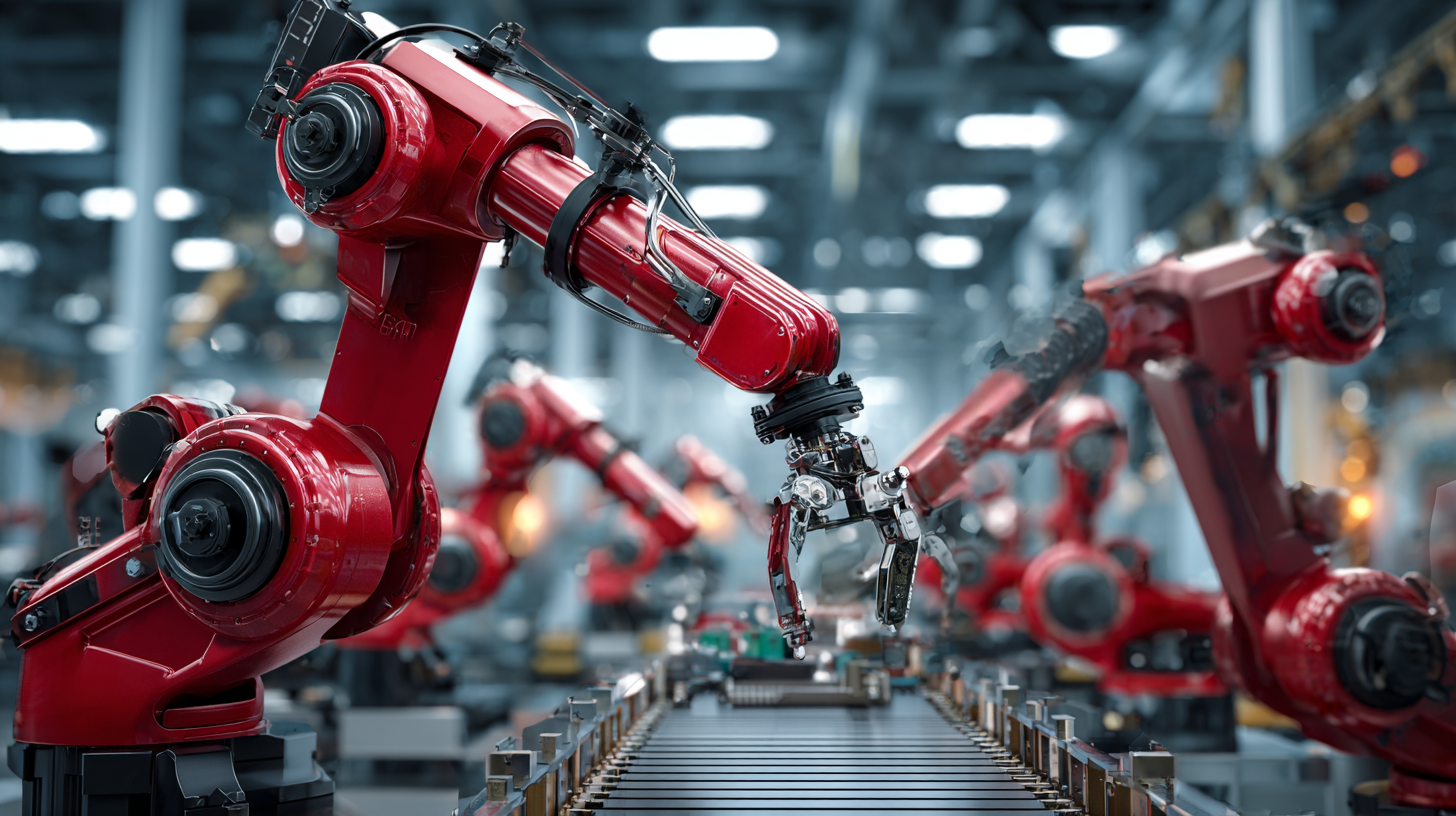

Exploring the Future of Manufacturing Robots in Smart Factories

The rapid evolution of technology in recent years has fundamentally transformed the manufacturing landscape, with manufacturing robots playing a pivotal role in this shift. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record high of 384,000 units in 2020, demonstrating a staggering growth of 12% compared to the previous year. This surge is indicative of the increasing adoption of automation and smart technologies within factories. As we look towards the future, the integration of manufacturing robots in smart factories is set to redefine operational efficiency and productivity.

With advancements in artificial intelligence, Internet of Things (IoT), and machine learning, these robots are becoming increasingly capable of performing complex tasks with precision and flexibility. The projected growth of the global smart manufacturing market, expected to reach USD 520 billion by 2025, underscores the critical role that manufacturing robots will play in shaping the factories of tomorrow.

How to Integrate AI into Manufacturing Robots for Enhanced Efficiency

The integration of AI with digital twin technology stands at the forefront of enhancing efficiency in manufacturing robots, particularly within smart factories. This synergy allows for sophisticated simulation designs and high-resolution modeling, making precise manufacturing processes not only feasible but also remarkably efficient. By utilizing real-time data from the digital twin, manufacturers can optimize the operation of welding robots, improving both speed and accuracy in tasks such as arc welding, laser welding, and spot welding. This capability is essential for various sectors including automotive, aerospace, and electronics, which rely on high-quality production standards.

Furthermore, the ongoing advancements in the industrial welding robot market are significantly influenced by the growing trend of incorporating AI-driven analytics. Such analytics enable predictive maintenance and adaptive learning, ultimately increasing the lifespan and functionality of these robots. This results in reduced downtime and operational costs, thereby directly contributing to market growth. As industries continue to embrace these innovative applications, the demand for welding robots is expected to rise, reflecting a broader trend of efficiency and technological integration in manufacturing processes.

Exploring the Future of Manufacturing Robots in Smart Factories - Data Overview

| Aspect | Description | Current Impact (%) | Future Impact (%) | Integration Difficulty (1-5) |

|---|---|---|---|---|

| AI-Based Predictive Maintenance | Use of AI for predicting maintenance needs to prevent downtime | 30 | 60 | 3 |

| Autonomous Navigation | Robots utilizing AI for obstacle detection and route optimization | 25 | 55 | 4 |

| Robotic Process Automation (RPA) | AI integration for automating repetitive tasks | 40 | 70 | 2 |

| Quality Inspection | Using AI vision systems for real-time quality control | 35 | 75 | 3 |

| Collaborative Robots (Cobots) | AI-driven robots designed to work alongside human workers | 20 | 65 | 4 |

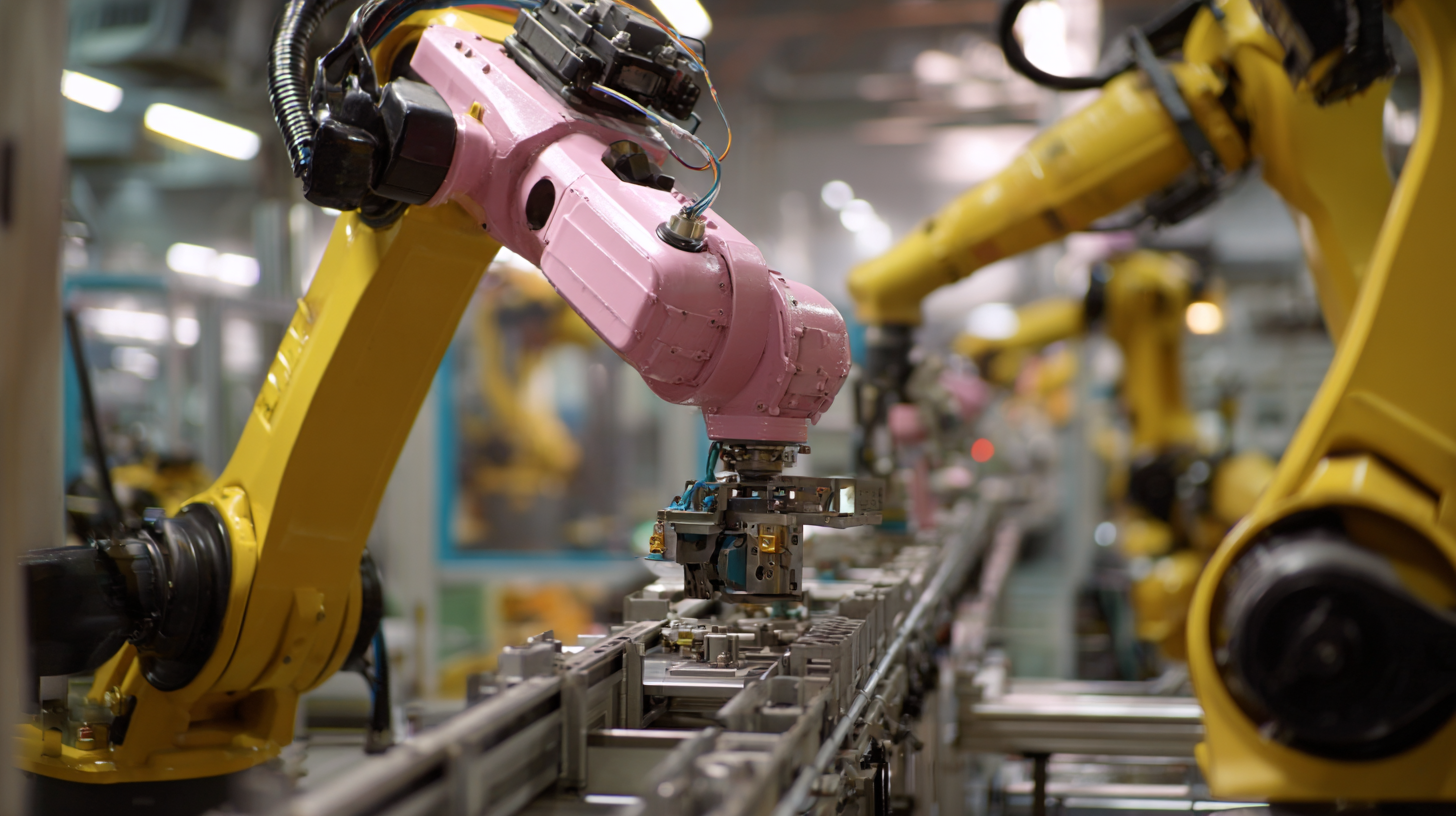

How to Design Smart Factories that Optimize Robotic Workflow

As industries move toward smart factories, designing environments that optimize robotic workflows is crucial for maximizing productivity and efficiency. According to a report by McKinsey, automated workflows can lead to a productivity increase of up to 30% in manufacturing sectors when properly integrated. To achieve this, factories must employ a combination of advanced robotics technologies and intelligent systems that facilitate seamless communication among machines and humans.

Incorporating IoT (Internet of Things) devices is essential in creating a responsive manufacturing environment. Data from Statista indicates that the global market for IoT in manufacturing is expected to reach $1.6 trillion by 2025. Smart factories should leverage real-time data analytics to adjust robotic tasks dynamically, ensuring optimal resource allocation and minimizing downtime. By using predictive maintenance algorithms, companies can also preemptively address potential equipment failures, further enhancing workflow efficiency. The design of these smart facilities demands an interdisciplinary approach, integrating robotics, AI, and data analytics to create a truly optimized and adaptable manufacturing process.

How to Ensure Seamless Communication between Robots and IoT Devices

As the manufacturing industry evolves, the future of robots in smart factories hinges on the vital communication between automated systems and IoT devices. With the rise of Industry 4.0, it is crucial for robots to seamlessly interface with interconnected devices to optimize production efficiency. Reports indicate that by 2025, the global IoT market in manufacturing is expected to reach approximately $1 trillion, highlighting the growing importance of integrated communication.

Ensuring seamless communication involves adopting standardized protocols and leveraging advanced technologies such as edge computing and AI. A recent industry report noted that 70% of manufacturers are prioritizing real-time data exchange capabilities to enhance operational responsiveness. This shift not only supports improved decision-making but also facilitates predictive maintenance and reduced downtime, which are essential for maintaining competitiveness in an increasingly crowded market. As more players join the educational hardware space, the principles of differentiation will also extend to robotic solutions, emphasizing the need for innovative collaboration between robotic systems and IoT to remain relevant and effective.

How to Implement Advanced Safety Protocols for Collaborative Robots

Collaborative robots, or cobots, are becoming integral to smart factory operations, promoting efficiency and innovation. Implementing advanced safety protocols is essential to ensure the seamless integration of these robots into human environments.

First, risk assessment must be conducted to identify potential hazards posed by robot movements and interactions with human workers. This assessment should inform the design of safety features, such as force-limiting technology that allows robots to operate safely in close proximity to people.

Furthermore, establishing effective communication systems between robots and human operators is crucial for safety. This can be achieved through the use of sensors and real-time monitoring systems that provide immediate feedback to both robots and workers.

Training personnel to understand these safety systems is equally important; workers must be educated on how to interact with cobots and recognize their operational limits. By prioritizing these advanced safety protocols, manufacturers can leverage the benefits of collaborative robots while fostering a secure and productive working environment.

How to Measure and Analyze Robot Performance in Smart Manufacturing Environments

In the rapidly evolving landscape of smart manufacturing, the performance measurement and analysis of robots are critical to ensuring operational efficiency and productivity. According to a report published by McKinsey, companies that effectively harness data analytics can improve their overall equipment effectiveness (OEE) by up to 20%. By implementing advanced metrics such as cycle time, uptime, and quality yield, manufacturers can gain valuable insights into robot performance, identifying both strengths and areas in need of improvement.

Furthermore, the integration of IoT devices within smart factories allows for real-time monitoring of robotic systems. A study from Deloitte indicates that 70% of manufacturing executives believe that real-time performance data will be crucial for making informed operational decisions. By leveraging data analytics platforms that aggregate robot performance metrics and historical data trends, manufacturers can accurately forecast maintenance needs and optimize production schedules. This proactive approach not only reduces downtime but also enables a more agile response to changes in consumer demand, tailoring robot operations to meet production requirements efficiently.