Top 10 Importance of xyz gantry in Modern Manufacturing Systems?

In today’s fast-paced industrial landscape, the xyz gantry plays a crucial role in enhancing manufacturing efficiency. According to a recent report by MarketsandMarkets, the global gantry crane market is projected to grow to USD 3.5 billion by 2026. The xyz gantry stands out due to its precision and versatility. It’s employed in various sectors, from automotive to aerospace fabrication.

Manufacturers value the xyz gantry for its ability to automate complex tasks. Automation can increase productivity by up to 30%, as indicated by a McKinsey study. However, relying solely on automation can lead to over-dependence on technology. Continuous monitoring and human oversight remain essential. The xyz gantry can also be expensive to implement and maintain, prompting companies to reflect on cost-effectiveness.

As industries strive for digital transformation, the xyz gantry’s significance grows. However, the integration process can be challenging. Firms must carefully evaluate their needs and capabilities. Balancing technology and human skill is critical for long-term success. The xyz gantry could revolutionize manufacturing, but its implementation requires thoughtful consideration.

Top 10 Importance of XYZ Gantry in Modern Manufacturing Systems

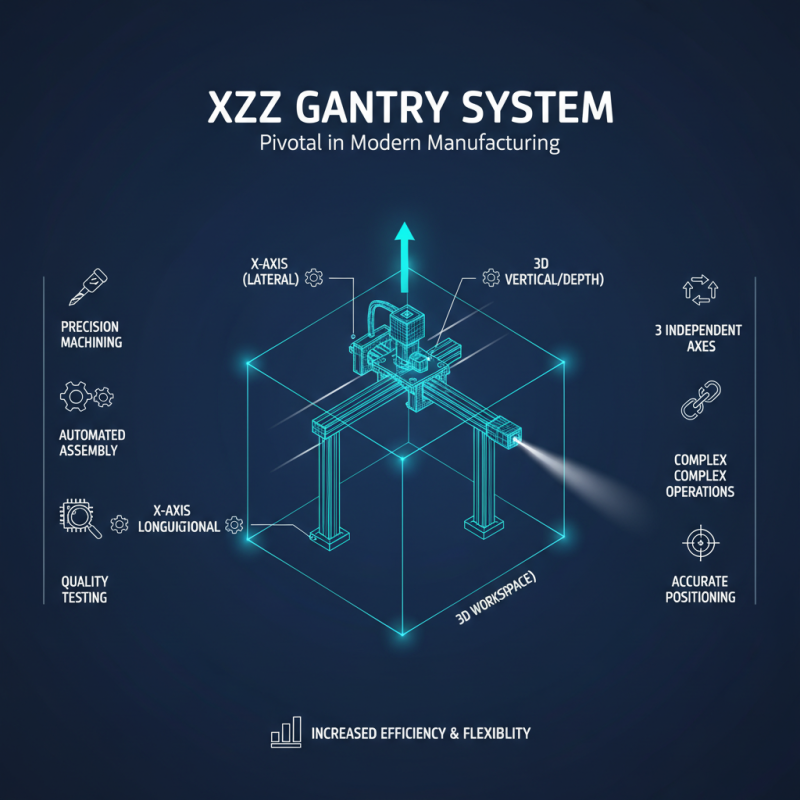

In modern manufacturing systems, the XYZ gantry plays a crucial role. It provides precision and efficiency in various applications. The design allows for smooth movements along three axes. This versatility increases productivity in factories and workshops. Companies increasingly rely on these systems to enhance their workflows.

One significant advantage is the ability to automate tasks. Automation reduces human error and increases repeatability. However, integration can be challenging. Not every factory adapts well to this technology. There can be initial costs and a learning curve. Many manufacturers find that training staff is essential for maximizing the gantry's potential.

Maintenance is another aspect to consider. Regular checks ensure optimal performance. Sometimes, overlooked components can cause delays. The gantry system, while advanced, requires careful thought in setup and operation. Continuous improvement is vital for leveraging its full benefits in an ever-evolving industry.

Top 10 Importance of XYZ Gantry in Modern Manufacturing Systems

| Importance Factor | Description | Impact on Manufacturing |

|---|---|---|

| Precision | Ensures high accuracy in positioning and machining. | Reduces waste and improves product quality. |

| Flexibility | Can be easily adapted for different manufacturing processes. | Facilitates production of diverse products. |

| Automation | Supports automated tasks with minimal human intervention. | Increases efficiency and reduces labor costs. |

| Space Utilization | Optimizes the use of factory floor space. | Enhances overall production capacity. |

| Speed | Increases the speed of manufacturing processes. | Reduces time-to-market for products. |

| Safety | Incorporates safety features to protect workers. | Minimizes workplace accidents. |

| Cost Efficiency | Reduces operational costs through efficient processes. | Enhances profitability of manufacturing operations. |

| Integration | Seamlessly integrates with other manufacturing technologies. | Improves workflow and process coordination. |

| Sustainability | Reduces energy consumption and waste. | Promotes environmentally friendly manufacturing. |

| Scalability | Easily scalable to meet growing production demands. | Supports business growth and expansion. |

Understanding the XYZ Gantry: Definition and Functionality

The XYZ gantry is a pivotal component in modern manufacturing systems. Its design consists of three axes: X, Y, and Z. This configuration allows for precise movement in a three-dimensional space. Such capabilities are vital for tasks like machining, assembly, and testing. Each axis operates independently, enabling complex operations without interference.

Functionality is at the heart of the XYZ gantry. It provides flexibility in how components are handled. Operators can program intricate paths for the gantry, allowing it to cover large areas efficiently. However, installing an XYZ gantry requires careful planning. Space optimization is crucial. Poor layout can lead to inefficiencies and increased costs.

Moreover, the gantry's maintenance often presents challenges. Regular checks are necessary to ensure optimal performance. But many manufacturers overlook this aspect. Neglect can lead to unexpected downtimes. Balancing accessibility and performance is a constant struggle. The effectiveness of the XYZ gantry relies on addressing these issues.

Enhancing Precision and Accuracy in Manufacturing with XYZ Gantry

The use of XYZ gantries has revolutionized modern manufacturing systems. These precise and versatile systems enhance accuracy in various production processes. With their ability to move along three axes, these gantries offer remarkable flexibility. This allows for more intricate designs that meet strict tolerances, making them essential for high-quality manufacturing.

However, implementing an XYZ gantry system isn’t without challenges. Calibration can sometimes be a cumbersome task, requiring skilled technicians. Misalignment can lead to costly errors or defects. The initial investment in these systems can be significant, which may deter smaller manufacturers. There’s a balance to maintain between cutting-edge technology and practical application.

Despite these hurdles, the benefits of XYZ gantries often outweigh the drawbacks. Industries have seen increased productivity and reduced waste. Precision improves production consistency, which is vital for customer satisfaction. In an era of rapid technological advancement, businesses must assess their needs and resources carefully. Embracing these systems can lead to greater competitiveness in the long run.

Top 10 Importance of XYZ Gantry in Modern Manufacturing Systems

Boosting Efficiency: The Role of XYZ Gantry in Production Processes

The XYZ gantry plays a pivotal role in modern manufacturing systems. Its structure allows for precise movement and positioning of tools and materials. This enhances production speed significantly. Consequently, manufacturers can meet tight deadlines. The efficiency of production processes is often a game changer.

In production lines, the XYZ gantry can handle various tasks. It manipulates heavy loads and small parts alike with ease. Automated systems often rely on this technology. Yet, issues such as rigidity and synchronization sometimes arise. These challenges can lead to production delays. Addressing them demands continuous improvement and innovative thinking.

Equipping facilities with an XYZ gantry introduces a new level of flexibility. It can adapt to different product types without extensive reconfiguration. However, ongoing training for operators is necessary. Skilled workers are crucial for optimizing this tech. Therefore, manufacturers should regularly evaluate their training programs. It’s essential to ensure that the workforce can fully exploit the gantry's potential.

Cost-Effectiveness of Implementing XYZ Gantry in Manufacturing Systems

In modern manufacturing systems, the XYZ gantry plays a crucial role in boosting efficiency. Its implementation can lead to significant cost savings for companies. A report from the Manufacturing Institute states that automation can reduce operational costs by up to 30%. This highlights the cost-effectiveness of integrating an XYZ gantry into existing workflows.

Moreover, these systems often require an initial investment, which can be daunting. However, studies have shown that businesses typically recoup these costs within two years. A survey by the National Association of Manufacturers revealed that 40% of firms experienced increased productivity post-implementation. These figures suggest that, while the upfront costs may be high, the long-term savings and productivity gains are substantial.

There are challenges in adapting to new technologies. Some employees may resist change, and training is essential. Yet, the potential return on investment makes it a worthy endeavor. As the industry evolves, embracing innovations like the XYZ gantry will be vital for staying competitive and achieving cost-effectiveness.

Conclusion

The XYZ gantry plays a crucial role in modern manufacturing systems, offering enhanced precision and accuracy that drive production efficiency. This advanced equipment operates by moving along three axes, allowing for intricate design and precise movements essential for modern manufacturing demands. Its ability to streamline processes significantly boosts overall productivity while reducing operational costs, making it a cost-effective solution for manufacturers.

Furthermore, the future of the XYZ gantry is bright, with ongoing innovations poised to incorporate advanced technologies such as automation and smart sensors. As manufacturing industries continue to evolve, the integration of XYZ gantry systems is expected to be at the forefront, making them indispensable for achieving higher efficiency and quality standards in production processes.

Related Posts

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

-

Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing

-

What is a Manufacturing Robot and How It Revolutionizes Modern Industries

-

What is Automated Storage and How Does it Benefit Your Business

-

Why Is Automated Storage Essential for Modern Businesses?

-

Top Types of Cartesian Robots in Automation and Their Applications?