Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today

In today's fast-paced industrial landscape, maximizing efficiency is not just an option but a necessity for businesses striving to maintain a competitive edge. The modern gantry system has emerged as a pivotal solution, enabling seamless integration of automation and advanced technology to enhance operational performance. As industries evolve, several key trends and innovations are reshaping the capabilities of gantry systems, making them more versatile and efficient than ever before. This article explores the latest advancements in gantry system design, including smart technology integration, improved motion control, and adaptable configurations, while also providing practical tips on implementation and optimization. By understanding these critical trends, businesses can leverage gantry systems to streamline their workflows, reduce downtime, and ultimately drive productivity in their operations.

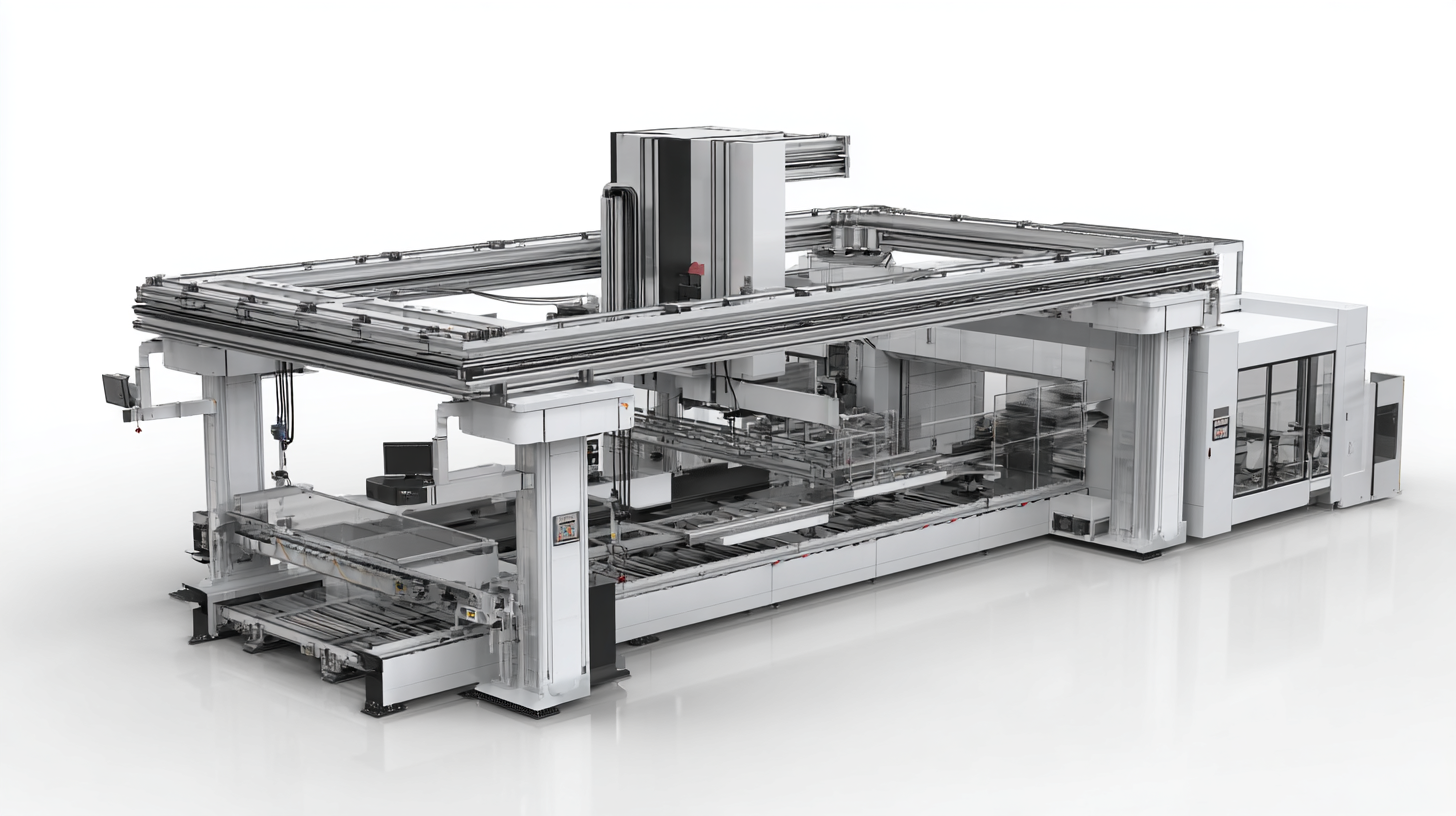

Emerging Technologies Revolutionizing Gantry Systems

Emerging technologies are transforming gantry systems, enhancing their efficiency and capabilities in various industries. One significant trend is the integration of automation and robotics, which allows for more precise and faster operations. Automated gantry systems can handle complex tasks with minimal human intervention, reducing the risk of errors and increasing overall productivity. This seamless integration not only streamlines workflow but also enhances safety by minimizing exposure to hazardous environments.

Another noteworthy innovation is the incorporation of advanced sensors and IoT (Internet of Things) technology. These smart gantry systems are equipped with real-time data analytics that monitor operational health and performance metrics. Such capabilities enable predictive maintenance, ensuring that equipment runs optimally and reducing unexpected downtime. Additionally, these systems can communicate with other machinery within the manufacturing process, creating a more cohesive and efficient operational ecosystem. As these technologies continue to evolve, they are paving the way for a new era of gantry systems that are not only more efficient but also smarter and more adaptable to the ever-changing demands of the industry.

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations

This chart displays the adoption rates of key trends and innovations in gantry systems. The data highlights areas such as automation and energy efficiency, showcasing how modern technologies are reshaping the industry.

Integration of IoT for Enhanced Operational Monitoring

The integration of the Internet of Things (IoT) into modern gantry systems is transforming operational monitoring and efficiency. According to a recent report by MarketsandMarkets, the global IoT in manufacturing market is projected to grow from $45.3 billion in 2022 to $110.6 billion by 2026, indicating an impressive compound annual growth rate (CAGR) of 19.2%. This surge demonstrates the increasing reliance on IoT technology to enhance real-time data collection and analytics, vital for effective gantry system operations.

By incorporating IoT devices, manufacturers can leverage data to monitor equipment performance, predict maintenance needs, and optimize workflows. A case study conducted by the International Data Corporation (IDC) illustrates that companies implementing IoT solutions have reported a 10% increase in operational efficiency and a reduction in downtime by as much as 30%. With sensors and smart devices collecting vast amounts of data from gantry systems, organizations can make informed decisions swiftly, drastically improving throughput and resource management while reducing operational costs. This trend signifies a shift towards smarter, more responsive manufacturing environments, driven by the profound capabilities of IoT technology.

Sustainability Practices in Modern Gantry Design

In the rapidly evolving landscape of gantry systems, sustainability practices are becoming a pivotal focus in modern design. According to a report by the International Energy Agency (IEA), energy efficiency improvements in material handling equipment, such as gantry cranes, can lead to energy savings of up to 30%. This transition towards sustainable practices reflects the industry's awareness of its environmental impact and the increasing regulatory pressures for greener operations.

Recent innovations in gantry design are embracing lightweight materials and energy-efficient technologies. For instance, studies indicate that the adoption of advanced materials like carbon fiber composites can reduce overall weight and increase load capacity without compromising structural integrity. Additionally, integrating electric or hybrid systems in gantry cranes can significantly cut emissions. The American Society of Civil Engineers (ASCE) projects that implementing these sustainable technologies can result in a 20-40% reduction in operational costs over the lifecycle of the equipment.

Furthermore, many industry leaders are incorporating smart technologies to optimize performance and minimize waste. By utilizing IoT sensors and AI algorithms, modern gantries can monitor energy consumption in real-time, allowing for adjustments that enhance efficiency. A recent report from McKinsey underscores that companies adopting these innovative approaches are not only amplifying their competitive edge but also paving the way for a more sustainable and responsible future in the gantry systems sector.

Automation and Robotics: Driving Efficiency Forward

The integration of automation and robotics in modern gantry systems is revolutionizing the way industries approach efficiency. A recent industry report from McKinsey highlights that automation can boost productivity by up to 30% within manufacturing processes, underscoring the significant potential for gantry systems. By incorporating advanced robotics, businesses can minimize manual handling, reduce error rates, and optimize workflows, leading to enhanced operational performance.

When looking to implement automation in gantry systems, organizations should focus on several key aspects to maximize efficacy. **Tip:** Consider investing in modular robotic solutions that can be easily integrated into existing systems and scaled as production needs grow. This adaptability allows for swift adjustments in response to market demands without substantial overhauls of existing infrastructure.

Moreover, advancements in artificial intelligence are powering smarter decision-making capabilities within these systems. According to a report by Deloitte, companies that adopt AI-driven solutions can achieve up to 20-30% improvements in efficiency and a notable reduction in operational costs. **Tip:** Regularly update software and training for employees interacting with these technologies to ensure you harness the full potential of intelligent automation.

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today

| Trend/Innovation | Description | Impact on Efficiency | Adoption Rate (%) |

|---|---|---|---|

| Autonomous Operation | Utilizing AI and sensors for unmanned navigation and handling of materials. | Increases throughput and reduces labor costs. | 65 |

| Modular Design | Flexible gantry systems that can be easily modified or expanded. | Allows for quick adaptation to changing production needs. | 70 |

| Enhanced Data Analytics | Integration of IoT devices to monitor performance and efficiency metrics. | Promotes informed decision-making and predictive maintenance. | 75 |

| Energy Efficiency | Implementation of systems that reduce energy consumption. | Reduces operational costs and environmental impact. | 60 |

| Collaborative Robotics | Introduction of robots that work alongside human operators. | Enhances productivity and safety in operations. | 68 |

Future Trends in Gantry System Customization and Flexibility

The landscape of gantry systems is evolving rapidly, driven by the need for customization and flexibility in advanced manufacturing. With the rise of smart factories, manufacturers are prioritizing adaptable gantry systems that can meet diverse operational requirements. Tailoring these systems to specific workflows enhances productivity and reduces downtime, paving the way for more efficient processes.

Tips: When considering customization, evaluate the specific needs of your operations. Understanding the tasks at hand will help in selecting the right features and configurations for your gantry system.

Moreover, innovations in software integration allow for seamless communication between gantry systems and other machine tools. This interconnectivity not only optimizes performance but also facilitates real-time data analysis, enabling better decision-making in manufacturing processes.

Tips: Invest in systems that offer advanced software solutions and cloud connectivity to maximize the efficiency of your gantry operations. This can lead to improved accuracy, reduced energy consumption, and enhanced overall productivity.