2026 How to Optimize Automated Material Handling for Efficiency?

In the ever-evolving field of automated material handling, efficiency is paramount. Industry expert Dr. Emily Chen once stated, “Maximizing efficiency starts with understanding every aspect of the process.” This insight highlights the importance of scrutinizing workflows and integrating advanced technologies.

Automated material handling systems are designed to streamline operations. However, many businesses struggle with optimally utilizing these solutions. An inefficient system can lead to increased costs and delays. For example, a warehouse integrating robotics without proper planning may encounter workflow bottlenecks. Such pitfalls underline the necessity of a thorough review before implementation.

Moreover, continuous growth demands regular reassessment of existing systems. Companies must question if their automated material handling systems meet their evolving needs. A focus on data analytics can reveal hidden inefficiencies. Thus, businesses must be open to adapting their strategies and technologies. Emphasizing refinement and adaptability is key in this competitive landscape.

Understanding Automated Material Handling Systems

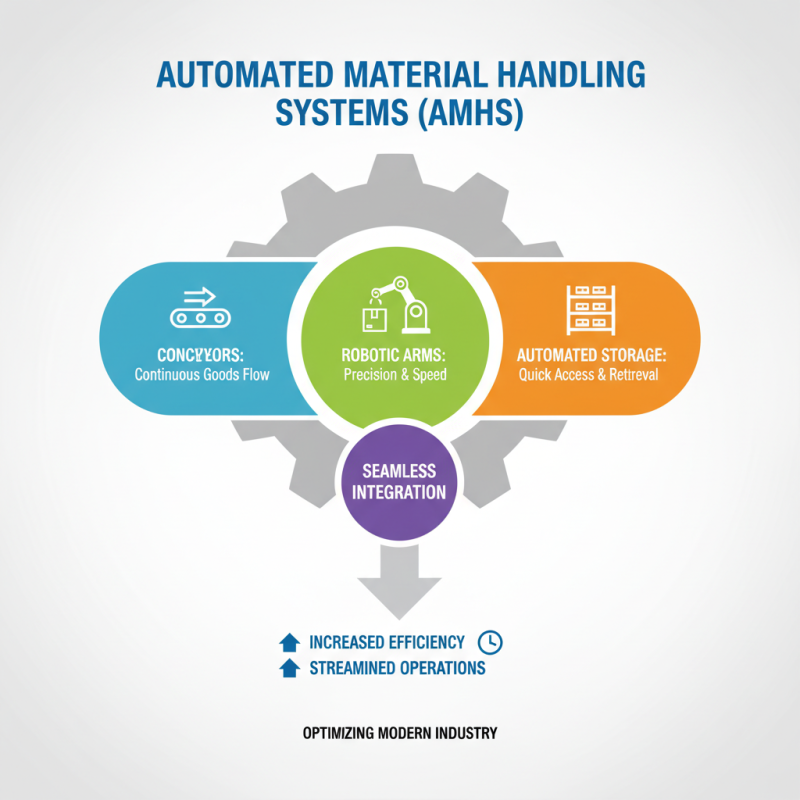

Automated Material Handling Systems (AMHS) play a crucial role in modern industries. They streamline the movement of goods, increasing efficiency. However, optimizing these systems requires a deeper understanding of their components. Key elements include conveyors, robotic arms, and automated storage systems. Each component must work seamlessly together for maximum output.

Tips for optimization: Focus on layout design. The physical arrangement of equipment can impact flow rates. Consider traffic patterns and potential bottlenecks. This can lead to faster processing times. Additionally, regular maintenance is vital. Neglecting this can cause downtime.

Another area to reflect on is data management. Collecting and analyzing data helps identify inefficiencies. Real-time tracking systems provide insights into performance. However, many organizations struggle with data overload. Prioritize the metrics that matter most. This prioritization can guide actionable changes in operations.

Key Components of Automated Material Handling for Efficiency

Automated material handling plays a crucial role in enhancing operational efficiency. Among key components, conveyors are vital. They streamline the movement of goods, reduce handling time, and minimize worker fatigue. According to a recent industry report, companies that use advanced conveyor systems have seen a reduction in operational costs by up to 20%. Still, misalignment or improper setup can lead to bottlenecks, negating these benefits.

Another significant aspect is automated storage and retrieval systems (ASRS). They offer optimized space utilization and allow for quicker access to materials. Reports show ASRS can increase storage density by 60% while decreasing retrieval times. However, the initial investment and ongoing maintenance can deter some organizations. It's essential for companies to conduct a thorough cost-benefit analysis before implementation.

Finally, implementing robotics in material handling enhances precision and speed. Robots can handle repetitive tasks, reducing human error. Yet, a well-designed integration plan is crucial. Poorly configured workflows may lead to chaos instead of efficiency. Striking the right balance between automation and human resources is fundamental for success in automated material handling.

Strategies for Optimizing Workflow in Material Handling

Optimizing workflow in material handling is vital for enhancing efficiency. Streamlining processes can reduce time and costs. One effective strategy is to analyze current workflows. Identify bottlenecks and areas for improvement clearly. For instance, if materials frequently jam during transport, consider revising the layout.

Tips: Regularly assess equipment performance. Look for signs of wear and slow operation. Sometimes, maintenance is ignored, leading to inefficiencies. Small adjustments often yield significant results. Don't underestimate the impact of operator training.

Another important aspect is technology integration. Automated systems can maximize speed and accuracy. However, they require careful planning. Address potential challenges, like employee resistance to change. Collect feedback to refine the system.

Tips: Use data analytics to track performance. Identify trends and make informed adjustments. Remember, not every change will be successful on the first try. Continuous reflection and adaptation are key to a thriving material handling operation.

2026 How to Optimize Automated Material Handling for Efficiency? - Strategies for Optimizing Workflow in Material Handling

| Strategy | Description | Expected Outcome | Implementation Timeframe |

|---|---|---|---|

| Automated Guided Vehicles (AGVs) | Use AGVs for transporting materials to reduce manual handling. | Increased transport speed and reduced labor costs. | 3-6 months |

| Warehouse Management Systems (WMS) | Implement advanced WMS to streamline inventory management. | Improved inventory accuracy and reduced order fulfillment time. | 6-12 months |

| Robotic Process Automation (RPA) | Integrate RPA for repetitive tasks in inventory management. | Enhanced efficiency and reduced human error. | 4-8 months |

| Data Analytics | Utilize data analytics to monitor and optimize material flow. | Informed decision-making and improved operational efficiency. | 2-5 months |

| Dynamic Slotting | Implement dynamic slotting for optimal product placement. | Reduced picking time and increased space utilization. | 3-6 months |

Technological Innovations in Material Handling Optimization

In the quest for efficiency, technological innovations play a crucial role in optimizing automated material handling. Real-time data analytics can significantly improve operations. By monitoring the movement of goods, companies can identify bottlenecks and streamline processes. This visibility allows for rapid adjustments to workflows, enhancing productivity.

Tips: Utilize sensors and smart tags. They can track items in transit. This helps in reducing errors. Regular audits are essential, too. Assess system performance often to ensure it aligns with goals. Automated alerts can notify staff about delays or irregularities, maintaining smooth operations.

Another innovation is the use of robotics. Automated guided vehicles (AGVs) can transport products quickly. However, integration with existing systems can be challenging. Companies often face difficulties in ensuring compatibility. Training employees to work with these systems is vital. Skilled workers can adapt to new tools efficiently.

Tips: Emphasize training for your staff. Schedule regular sessions to keep them updated. Engage with them for feedback on processes. Their insights can lead to unexpected improvements. Small changes can have a big impact on efficiency.

2026 How to Optimize Automated Material Handling for Efficiency

Measuring and Analyzing Performance in Material Handling Systems

To optimize automated material handling, measuring and analyzing performance is crucial. Start with clear metrics to assess efficiency. Common metrics include throughput time, error rates, and equipment utilization. Regularly track these data points to identify trends. Are your automated systems underperforming? This can lead to serious bottlenecks.

Consider the layout of your system, too. Is it fostering smooth movement of goods? Ineffective designs can slow down operations. Use simulation tools to visualize potential changes. This may help in finding optimal routes for transport. Frequent evaluations can expose areas in need of adjustment. Perhaps certain machinery needs upgrades or replacements. Regular maintenance checks can also enhance reliability.

Don’t overlook the human factor. Employees should be adequately trained to work alongside automated systems. Their insights can provide valuable feedback on system performance. Communication between staff and technology leads to better efficiency. Always strive for continuous improvement, even when systems seem to run smoothly. Assess, adjust, and refine to keep up with evolving demands.

Related Posts

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

2026 Best Automated Material Handling Solutions for Efficient Warehousing?

-

How to Optimize ASRS Systems for Maximum Efficiency and Reliability?

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions