What is a pick and place robot and how does it work?

A pick and place robot is a vital tool in various industries. These robots are designed to handle items quickly and efficiently. They can pick up objects and place them in designated locations. This functionality is commonly seen in manufacturing and logistics.

The working principle of a pick and place robot involves using sensors and advanced algorithms. These robots identify objects and determine the best way to grip them. They can adapt to different shapes and sizes. However, challenges exist. For instance, gripping delicate items without damage can be tricky.

Understanding the intricacies of a pick and place robot helps highlight its significance. As industries evolve, the demand for precision and speed increases. This technology plays a crucial role in meeting those needs, but continuous improvement is essential. How can we enhance their accuracy further?

What is a Pick and Place Robot?

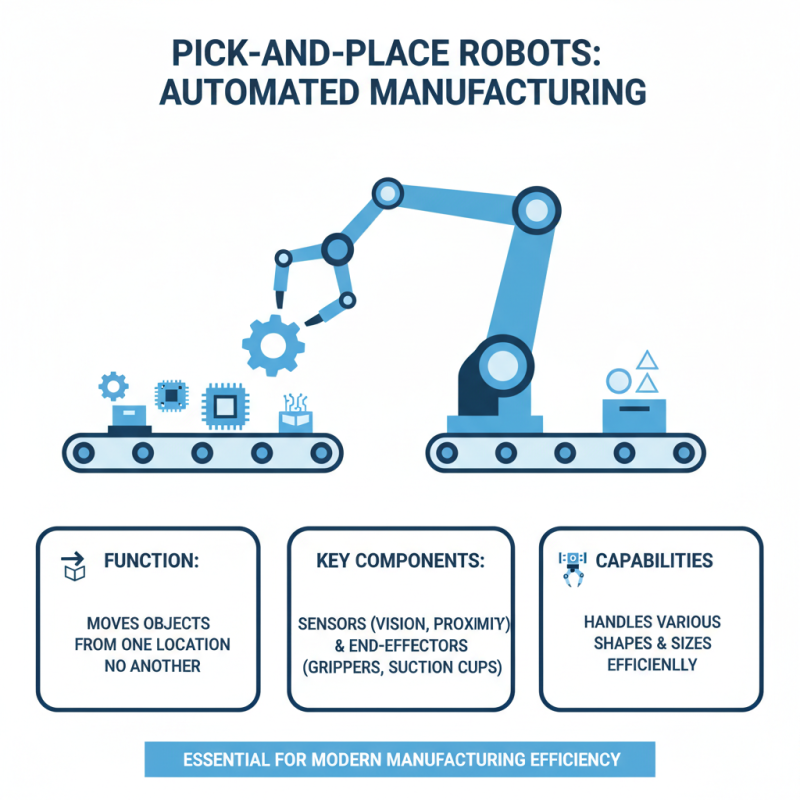

A pick and place robot is an essential component in modern manufacturing. It automates the process of moving objects from one location to another. These robots typically use a variety of sensors and end-effectors to grip items. They can handle various shapes and sizes quite efficiently.

These robots often excel in repetitive tasks. They are used in packaging, assembly, and quality control. Their ability to work quickly reduces human error. However, it's important to note that they can struggle with irregularly shaped objects. This limitation can impact workflow.

In some cases, programming these robots can be complex. The setup may take longer than expected. Ongoing maintenance is vital for optimal performance. As useful as they are, pick and place robots require careful consideration. Their role in manufacturing continues to grow, but challenges remain.

The Key Components of a Pick and Place Robot

A pick and place robot is designed for tasks like assembly and packaging. Its main components are crucial for functionality. The robotic arm is perhaps the most recognizable part. It mimics human arm movements, picking items from one place and placing them in another. Sensors help the robot identify objects and their locations.

The end effector, often a gripper or suction cup, is vital. It securely holds items during movement. The control system, which includes software and hardware, directs the robot’s actions. This system processes data from sensors and ensures accurate operation.

Tips: Ensure the workspace is clear. Crowded areas can confuse the robot's sensors. Regularly maintain your robot. Wear and tear can lead to errors. Keep an eye on the programming. Misconfigurations can cause repetitive mistakes. Planning and reflections are key to seamless operation.

The Working Mechanism of Pick and Place Robots

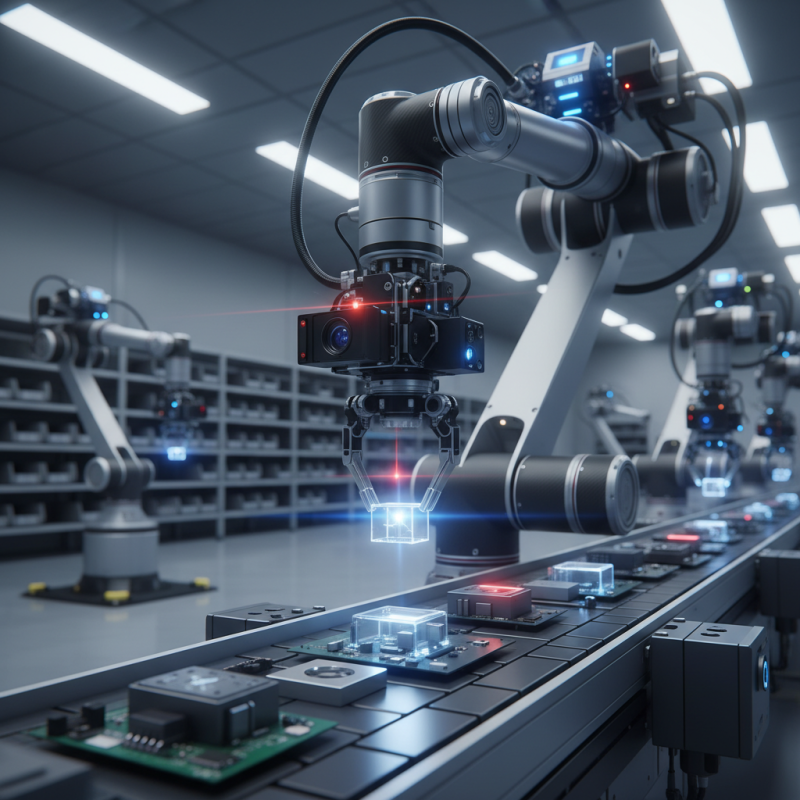

Pick and place robots are revolutionizing automation. They simplify the handling of objects in various industries. These robots utilize a combination of sensors, cameras, and artificial intelligence. Their goal is to move items efficiently and accurately.

The working mechanism involves several key components. A robotic arm usually carries a gripper or suction device. This tool picks up objects from one location and places them precisely in another. Sensors help the robot detect and identify items. They guide the robot's movements, ensuring that objects are handled correctly. The programming of these robots can be complex, yet it often requires adjustment and fine-tuning.

However, challenges remain. Not all items are easy to handle. Delicate or oddly shaped objects pose risks. Robots may need reprogramming to adapt to new tasks. Furthermore, maintaining these machines can be a hassle. Regular calibration is necessary to keep performance steady. Designing a system that works for all applications still demands creativity and effort.

Pick and Place Robot Usage Statistics

This chart illustrates the distribution of industries utilizing pick and place robots in 2023. The data reflects the percentage of usage across various sectors.

Applications of Pick and Place Robots in Various Industries

Pick and place robots are transforming various industries with their efficiency and precision. In manufacturing, these robots automate the movement of items along production lines. According to a recent industry report, the global market for industrial robots is expected to reach $70 billion by 2027. This growing adoption is driven by the need for speed and accuracy in production processes.

In the food and beverage sector, pick and place robots handle delicate items with care, enhancing productivity while reducing waste. Research shows that companies using these robots see a 15% increase in output. However, integrating these systems can pose challenges. There may be initial costs, maintenance concerns, and the need for employee training.

In the electronics industry, these robots facilitate the assembly of intricate components. They minimize human error and enhance quality control. A study found that 30% of electronic manufacturers report improvements in efficiency after adopting robotics. Nevertheless, reliance on automation raises questions about workforce displacement. As industries evolve, the balance between robotics and human labor remains a critical topic for reflection.

Benefits of Using Pick and Place Robots in Automation

Pick and place robots are transforming automation in various industries. Their primary benefit lies in efficiency. These robots can swiftly pick items from a designated location and place them with precision. This speeds up production lines significantly. Repetitive tasks become easy and quick. Workers can focus on complex activities instead.

Another advantage is the reduction of human error. Mistakes in manual handling can lead to costly errors. Robots provide consistent picking and placing, minimizing risks. They operate longer hours without fatigue. This leads to increased productivity. However, companies must ensure proper training for workers to handle these machines. Understanding limitations is essential.

Some challenges may arise. Initial setup and programming can take time. Maintenance is also critical to avoid downtime. Keeping the technology updated is necessary for optimal performance. Each of these factors requires reflection from management. Balancing automation with human oversight is important for success.

What is a pick and place robot and how does it work? - Benefits of Using Pick and Place Robots in Automation

| Feature | Description | Benefits |

|---|---|---|

| Operating Principle | Uses robotic arms to grasp and relocate parts or products. | Increases efficiency in material handling. |

| Types | Can be industrial, collaborative, or mobile robots. | Flexibility to suit various applications. |

| Application Areas | Used in manufacturing, packaging, and assembly lines. | Streamlines production processes. |

| Speed | Can operate at high speeds with precision. | Reduces cycle time and increases throughput. |

| Cost Efficiency | Lower operational costs compared to manual labor. | Improves ROI for automation investments. |

| Safety | Equipped with sensors for safe operation alongside humans. | Enhances workplace safety. |

Related Posts

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines