What is Robotic Arm Design and Its Applications?

Robotic arm design involves creating mechanical arms capable of performing various tasks. These arms can mimic human movement and execute precise actions. Industries utilize them for manufacturing, assembly, and even medical procedures.

In recent years, robotic arms have gained popularity. They can increase efficiency and precision in various applications. However, the design process can be complex and requires consideration of many factors. Materials, movement range, and control systems all play crucial roles.

Many designs face challenges. The balance between cost and functionality is often difficult to achieve. Additionally, the integration of advanced technologies poses its own set of problems. Designers must constantly reflect on how to improve robotic arm design for better performance and adaptability.

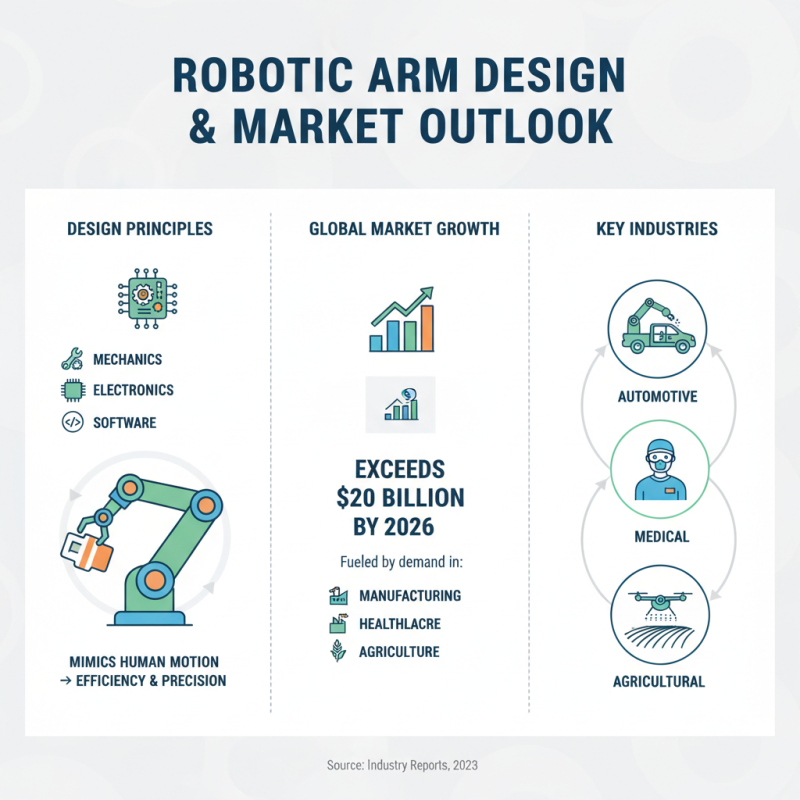

Overview of Robotic Arm Design Principles

Robotic arm design is crucial across various industries. It involves principles that meld mechanics, electronics, and software. These arms mimic human motion, enhancing efficiency and precision in tasks. According to industry reports, the global robotic arm market is expected to exceed $20 billion by 2026. This growth is fueled by demands in manufacturing, healthcare, and agriculture.

The design principles focus on degrees of freedom, payload capacity, and precision. The ideal arm can navigate complex tasks with multiple joints. However, achieving this requires careful calibration. Many designers struggle with balancing mobility and stability. A robotic arm needs to be robust yet flexible, an ongoing challenge in the field.

Tips: Start with simple designs. Gradually integrate more complex features as understanding of mechanisms improves. Be mindful of power requirements; an over-engineered arm could consume excess energy. Also, frequent testing is essential. Errors in design can lead to costly failures. Learning from these setbacks is part of the innovative process.

Key Components and Mechanisms of Robotic Arms

Robotic arms are fascinating devices. They mimic human arm movements. Their design combines several key components. Each part plays a vital role in function and efficiency.

One major component is the actuator. Actuators provide motion, using motors or hydraulic systems. They enable precise positioning of the arm. Sensors are another essential part. They help to detect the arm's position and surroundings. This feedback is crucial for accuracy. The control system ties everything together. It processes inputs from sensors and directs the actuators.

Yet, designing a robotic arm comes with challenges. Integration of parts can be complex. The balance between strength and flexibility must be just right. Too much power can lead to breaks. However, inadequate force might limit its capabilities. Continuous testing is required. This often leads to improvements and innovative solutions. Every iteration can provide new insights into design efficiency.

Applications of Robotic Arms in Industrial Automation

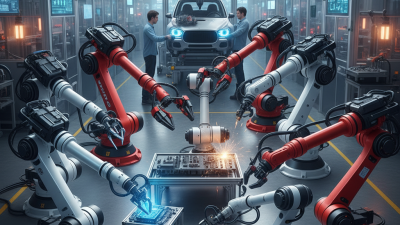

Robotic arms are transforming industrial automation. They provide precision and efficiency in various tasks. These arms can perform repetitive actions without fatigue. In manufacturing, they are used for welding, painting, and assembly. Their speed often surpasses human capabilities. This results in higher productivity and reduced errors.

Tips: When selecting robotic arms, consider their range of motion. A good design should fit the specific task. Moreover, ease of programming can make a difference. Look for user-friendly interfaces. Remember, not every application will benefit from robotic arms equally. Assess the environment before implementation.

In logistics, robotic arms assist in material handling. They pick, sort, and pack items swiftly. This reduces manual labor and lowers the risk of injuries. However, integrating these systems may pose challenges. Staff training is essential to ensure smooth operations. Moreover, unexpected machine failures can disrupt workflows. Address these issues with careful planning and testing.

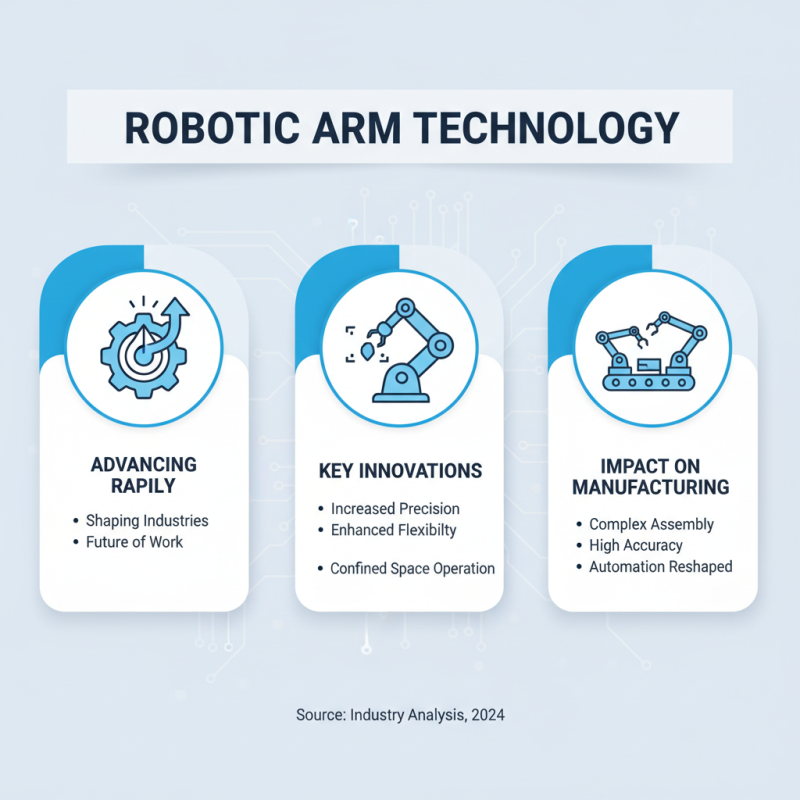

Emerging Trends in Robotic Arm Technologies

Robotic arm technology is advancing rapidly, shaping the future of various industries. Automation is more than a trend; it's reshaping how we work. New designs focus on increased precision and flexibility. This is evident in manufacturing, where robotic arms assemble complex products with high accuracy. The ability to operate in confined spaces is a game-changer.

Another emerging trend is collaboration. Robots and humans now work side by side. This requires better sensors and advanced programming. However, this innovation raises questions about safety and job displacement. Not every task is suitable for a robot. There’s a learning curve for both technology and workforce.

Sustainability is becoming a priority too. Developers aim to create energy-efficient arms. They look at materials that minimize environmental impact. However, achieving this balance is challenging. The demand for innovation sometimes conflicts with eco-friendly practices. Industry leaders must reflect on these dilemmas as technology evolves.

Challenges and Future Directions in Robotic Arm Design

The field of robotic arm design faces significant challenges. Designing arms that mimic human dexterity remains a hurdle. Many robotic arms today lack the nuanced movements necessary for complex tasks. A recent industry report indicated that only 30% of robotic arms effectively perform intricate tasks. This gap highlights the need for enhanced precision and flexibility in design.

Moreover, the integration of AI and machine learning poses both opportunities and obstacles. While AI can improve functionality, it also complicates programming. Engineers must ensure reliability and safety when incorporating intelligent systems. An estimated 40% of robotics engineers reported difficulties in achieving seamless AI integration. The result is often a lack of adaptability in real-world environments.

Looking forward, future designs must prioritize collaboration between humans and machines. Robotic arms should not only function autonomously but adaptively respond to human actions. Developing effective interfaces is crucial. As the demand for versatile robotic solutions grows, addressing these challenges will be essential for progress in this field.

What is Robotic Arm Design and Its Applications? - Challenges and Future Directions in Robotic Arm Design

| Dimension | Details |

|---|---|

| Types of Robotic Arms | Articulated, SCARA, Delta, Cartesian |

| Applications | Manufacturing, Healthcare, Research, Entertainment |

| Key Components | Actuators, Sensors, Controllers, End Effectors |

| Challenges | Precision, Flexibility, Cost, Integration |

| Future Directions | AI Integration, Enhanced Sensory Feedback, Autonomous Operations |

Related Posts

-

Top 10 Benefits of Using Industrial Robot Arms in Modern Manufacturing

-

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency

-

Top 10 Fanuc Robot Applications in Manufacturing and Automation Industry

-

Exploring the Future of Manufacturing Robots in Smart Factories